Керамическая пластина из карбида кремния/полки кремния/пластина SIC по лучшей цене

- Категории: Огнеупорные материалы >>>

- Поставщик: Zibo,Supereal,Industrial,Ceramic,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Silicon carbide ceramic plate / silicon carbide kiln shelves / SIC plate at best price

Questions & Answer ( This part is very helpful to you, it tells the centered questions that you may have or you are concerned, whether you are one frequent purchaser familiar with the silicon carbide plate or one new purchaser not so familiar with this product ).

Question 1: What is the working temperature of Supereal oxide bonded silicon carbide plate? Answer: Supereal silicon carbide plate working temperature is normally at 1200-1400C.

Question 2: What is the application of Supereal oxide bonded silicon carbide plate? Answer: Any application with working temperature below 1400C is OK. Mainly applied to household porcelain , sanitary ware , pottery and other industrial ceramics firing.

Question 3: How about the SiC content of Supereal oxide bonded silicon carbide plate? Answer: SiC content of Supereal silicon carbide plate ≥ 88%, which is one proven data because we tested our plate through NATIONAL QUALITY INSPECTION AND SUPERVISION CENTER FOR INDUSTRIAL CERAMICS OF BUILDING MATERIALS INDUSTRY .

Question 4: What is the density of Supereal oxide bonded silicon carbide plate?

Answer: ≥2.7g/cm3

Question 5: How about the thickness of Supereal oxide bonded silicon carbide plate?

Answer: usually at range of 10-50mm, but it depends on the length and width. If thin thickness (less than 10mm) and light weight is important to your application, pls consider our RSIC (Recrystallized silicon carbide plate) or RBSIC plate ( Reaction bonded silicon carbide plate)

Taking silicon carbide as the main material and adding expansion agent and anti oxidant, Silicon carbide ceramic plate / silicon carbide kiln shelves / SIC plate at best price have very high load softening temperature and excellent anti oxidative effect through vibration supported uniaxial press compaction and high temperature firing. It was originally used as an alternative to conventional bonded SiC materials, but it shows the long term stability comparable to RSiC and NSiC with lower cost.

1. Technical parameters of Silicon carbide ceramic plate / silicon carbide kiln shelves / SIC plate at best price

| ITEM | UNIT | DATA |

| Temperature | ℃ | 1400 |

| Density | g/cm³ | ≥2.7 |

| Open Porosity | % | <18 |

| Moh's Scale of Hardness | 13 | |

| Bending Strength | MPa | 250 (20℃) |

| MPa | 280 (1200℃) | |

| Modulus of Elasticity | GPa | 330 (20℃) |

| GPa | 300 (1200℃) | |

| Thermal Conductivity | W/m.k | 45 (1200℃) |

| Coefficient of thermal expansion | k-1×10-6 | 4.2 |

| Acid Alkaline -proof | Excellent |

2.Property:

Good thermal shock resistance

Good resistance against corrosion and oxdiation

Good mechanical strength at high temperature

Excellent thermal and electric conductivity

Long service life and energy saving

Environmental friendly

Other recommendations

Reaction Bonded SiC (SiSiC)

Recrystallizde SiC (RSiC)

Nitride Bonded SiC (NSiC)

3. Stock size for your choice

| 400x400x10mm | 500x500x13mm | 400x600x15mm | 480x500x15mm | 450x500x14mm | 280x280x12mm |

| 340x450x12mm | 450x450x15mm | 530x330x12mm | 370x500x13mm | 480x500x15mm | 300x350x10mm |

| 475x475x10mm | 370x500x15mm | 450x450x12mm | 400x400x10mm | 350x400x15mm | 500x480x12mm |

| 340x440x10mm | 370x500x20mm | 530x330x13mm | 550x600x15mm | 450x450x12mm | 500x500x15mm |

| 450x500x20mm | 600x600x15mm | 290x390x10mm | 300x300x12mm | 530x330x13mm | 450x550x14mm |

| 400x450x20mm | 400x600x20mm | 340x340x10mm | 500x600x15mm | 290x390x10mm | 600x620x20mm |

| 400x450x10mm | 450x500x15mm | 400x450x15mm | 500x500x30mm | 400x450x15mm | 400x600x12mm |

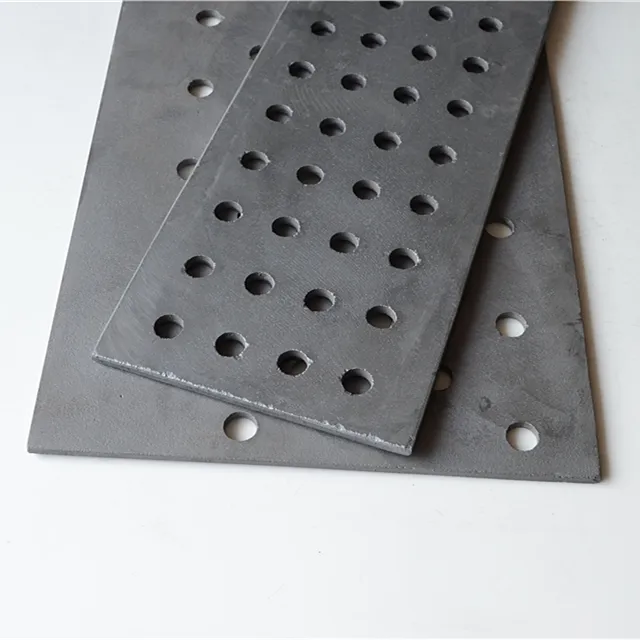

4. Shapes of Silicon carbide ceramic plate / silicon carbide kiln shelves / SIC plate at best price

Batts, setter plate, pusher plate, setter slab, sagger,muffle board,support shelves and other special shaped products

Remark: sizes and shape are available upon requests.

Some OSiC Oxide bonded silicon carbide parts is shown as follows:

5. Application of Silicon carbide ceramic plate / silicon carbide kiln shelves / SIC plate at best price

Our Silicon carbide ceramic plate / silicon carbide kiln shelves / SIC plate at best price can be made into OSiC plate, OSiC support, OSiC disc and other special shaped products, which are mostly used as kiln furniture like batts, setter plate, pusher plate, setter slab, sagger,muffle board and support shelves in firing tableware, sanitary ceramics, electrical ceramics, emery wheel and so on.

6. Packing for Silicon carbide ceramic plate / silicon carbide kiln shelves / SIC plate at best price

Zibo Supereal Industrial Co., Ltd, located in Zhangdian Economic Development Zone in Zibo city is focusing on high alumina ceramic products ( such as high alumina ceramic plates, rubber backed ceramic plates, wear resistant alumina tiles, abraisive protection ceramic lined pipe, and so on) and silicon carbide ceramic products including OSIC, NSIC, RBSIC and RSIC products, here you can realize an one-stop services in wide range of industries including Power Sector, Mining, Cement, Metallurgy, Coal Washing, Steel& Iron Plant, Ceramic industry, Kiln and So on.

Our company has one rigorous quality control system to guarantee stable performance and proven quality, our professional inspection team will carry out full course tracking from raw material selection, batching, production process management to semi and finished products test. Based on the strict adherence to ISO9001-2008 or Industry Standard or other International Standard, our products have been approved and accepted by clients and users from Australia, South Korea, India, Russia, South Africa, Turkey, USA, France and etc.

◊ Professional: More than ten years of experience in production, more than 5 years of experience in foreign trade export, we will supply prompt technical support on pre- and after sales.

◊ High Quality:Based on the strict adherence to ISO9001-2008 or Industry Standard or other International Standard, our inspection engineers carry out full course tracking in the whole production.

◊ Focus on Details: No matter how small questions or problems shall be replied and help to solve by our members, even for the small orders.

◊ Price &Discount: We can provide competitive price and discount for large quantity.

◊ OEM : Customized designs, sizes and logos are acceptable.