Металлический пузырьковый лоток для внутренней

- Категории: Chemical Machine Parts >>>

- Поставщик: Jiangxi,Eloong,Environmental,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Product Overview

Column Internal Column Tray Metal Bubble Cap Tray

Description:

The structure of the bubble cap tray is mainly composed of a blister (gas-liquid contact element), a gas riser, an overflow weir,a

downcomer and a tray.The bubble tray is provided with a plurality of round holes on the tray plate, and each hole is welded with a

short tube called a riser tube, and the tube is covered with a "hat" called a blister, and a plurality of strips are formed around

the blister. Hole,during operation, the liquid flows from the upper tray through the downcomer into the lower tray, then flows

laterally through the tray plate and flows into the next tray; the gas rises from the lower tray into the riser tube and passes

through the annular passage. The strip holes of the blister flow into the liquid layer between the blister.

Advantage:

(1) The gas and liquid phases are in full contact and the mass transfer area is large, so the tray efficiency is high.

(2) The operation flexibility is large, and the high efficiency can be maintained when the load variation range is large.

(3) It has high production capacity and is suitable for large-scale production.

(4) It is not easy to block, the medium adapts to a wide range, and the operation is stable and reliable

Application:

Mainly usend in reactive distillation, separation of certain organic products; separation of benzene-methyl; separation of

nitrochlorobenzene; oxidation and absorption of ethylene.

The structure of the bubble cap tray is mainly composed of a blister (gas-liquid contact element), a gas riser, an overflow weir,a

downcomer and a tray.The bubble tray is provided with a plurality of round holes on the tray plate, and each hole is welded with a

short tube called a riser tube, and the tube is covered with a "hat" called a blister, and a plurality of strips are formed around

the blister. Hole,during operation, the liquid flows from the upper tray through the downcomer into the lower tray, then flows

laterally through the tray plate and flows into the next tray; the gas rises from the lower tray into the riser tube and passes

through the annular passage. The strip holes of the blister flow into the liquid layer between the blister.

Advantage:

(1) The gas and liquid phases are in full contact and the mass transfer area is large, so the tray efficiency is high.

(2) The operation flexibility is large, and the high efficiency can be maintained when the load variation range is large.

(3) It has high production capacity and is suitable for large-scale production.

(4) It is not easy to block, the medium adapts to a wide range, and the operation is stable and reliable

Application:

Mainly usend in reactive distillation, separation of certain organic products; separation of benzene-methyl; separation of

nitrochlorobenzene; oxidation and absorption of ethylene.

Technical data | ||||||||

Size (Inch/mm) | Material | Number (per m3) | Surface area (m2/m3) | |||||

Customized | 6*6*0.3 | stainless steel, Monel, titanium, PP, PVC, PE, PTFE | 4000000 | 904 | ||||

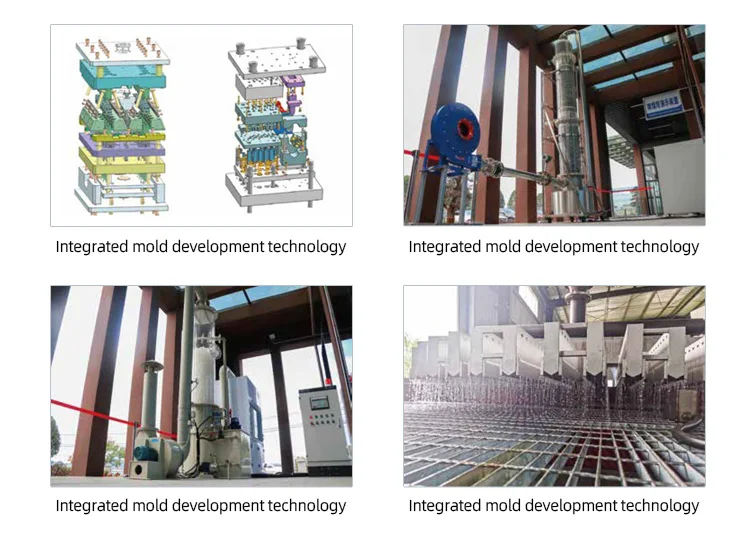

Our workshop

Plastic Random Packing Workshop

The injection molding workshop has 28 advanced production lines in the world. It adopts European standard large tonnage precision injection molding machine, equipped with three-axis servo manipulator, visual monitor and centralized feeding system to ensure that the annual output of 100000 cubic meters of finished products without any quality problems.

Tower internals workshop

The workshop is equipped with 2 * 6m 3000W large laser cutting equipment, servo CNC bending machine, CNC turret punch, laser welding machine, shearing machine and other high-end equipment. The workshop has an annual output of 8000 tons of trays and internals, and is equipped with automatic degreasing and pickling purification line.

Precision mold workshop

The workshop is equipped with the

CNC machining center ,CNC engraving

machine,large-scale electric pulse machine lathe,NC lathe,medium speed wire-cut EDM. Automation matching, molding technology molding, extrusion, stamping, blow molding, development, production improvement and efficiency improvement, covering injection rolling mold manufacturing capacity.

Intelligent Stereoscopic warehouse

The single cargo space largest intelligent warehouse in China, which is calculated and managed by WMS, WCS system.The whole integrated workshop through AGV automatic distribution, realize the unified collection and distribution of raw materials, finished products and packaging. The capacity of 80000 cubic meters that can store 20000 cubic meters of finished products & 3000 ton of raw material.

Metal Random packing Workshop

The workshop has 22 full-automatic stamping production lines, The original

multi process integrated stamping die is equipped with intelligent detection device, which is free of maintenance for 300000 times and repair free for 500000 times.With an annual output of 30000 cubic meters of finished products.

multi process integrated stamping die is equipped with intelligent detection device, which is free of maintenance for 300000 times and repair free for 500000 times.With an annual output of 30000 cubic meters of finished products.

Metal structured Packing Workshop

The metal structured packing workshop has an annual output of 20000 cubic meters of finished products. It is equipped with eight advanced high-speed stamping production lines. It adopts Sanyuan guideway machine equipped to stamping 600 times / min, and keep the forming accuracy within 0.1 mm. Also it is equipped with two top-level automatic plate wave production lines independently researched and developed.

Certifications

Customer Photos

Why Choose Us

Product packaging

SIMILAR PRODUCTS

FAQ

Q1:What's the MOQ?

A1 : The MOQ is 1 cubic meter or 1 ton, The price will be higher if the quantity is less than 1 cubic meter or 1ton.

Q2 : What are the terms of payment?

A2 : T/T , L/C at sight, Papal , Alibaba Trade Assurance and etc.

Q3 : What's the delivery time?

A3 : About 3-7 days .after received the fund.

Q4 : Can you provide free samples?

A4 : Yes , Sample will be free within 0.5 kg.

Q2 : What are the terms of payment?

A2 : T/T , L/C at sight, Papal , Alibaba Trade Assurance and etc.

Q3 : What's the delivery time?

A3 : About 3-7 days .after received the fund.

Q4 : Can you provide free samples?

A4 : Yes , Sample will be free within 0.5 kg.

Похожие товары

Низкая цена, новый тип, структурированная упаковка, поддерживающая сетка

US $100.00-$300.00

2021 Simple Grid Support for tower packing

US $420.00

SS304 304L 316 316L 410 металлическая структурная упаковка

US $500.00-$1900