Разная твердость резиновый миксер/машина для обработки резины/внутренний миксер

- Категории: Internal Mixers >>>

- Поставщик: Qingdao,Chaoguangyue,Industry,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Different hardness rubber power mixer / rubber processing machine / banbury internal mixer

High safety factor,low energy cost, high degree of production sanitation

Brief description

1.Excellent sealing performance(copper sealing ring)

2.No leakage of powder /oil-proof

3.Automatic and manual interaction

4.Rotors:chroming carbide alloy ,15 silk

5.Type of rotors:standard two-wing tangential rotor ,four-wing synchronous rotor ,welded up alloy rotor and cylindrical intermeshing rotor

Door drop type banbury mixer

Application of Rubber Kneader

The rubber mixer is mainly used for rubber or plastic mixing and plasticizing, or rubber and plastic blending. It is a type of economical, energy-saving and environmental friendly mixing equipment that widely used in the field of rubber and plastic product industries,

1. Rubber tire industry

2. Rubber product for automobile (oil seal, body seal, gasket, belt, hose, tube and etc)

3. Electric wires (rubber, plastic and wire harness and etc)

4. Belts (power transmission belt, conveyor belt and etc)

5. Rolls (rubber, plastic, printing, copying machine and etc)

6. Medical rubber products (plug, cap, glove, dental and etc)

7. Sporting equipments (golf ball, athletic balls and etc)

8. Food (chewing gum)

9. Other rubber or plastic compounding industry. (PVC, PE, PP, EVA, etc)

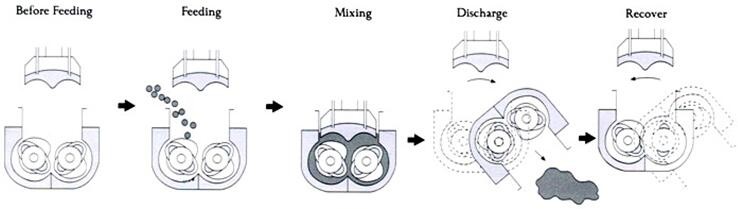

Working Principle of Rubber Kneader

The working principle of rubber mixer is similar to the ordinary banbury mixer. Under the pressure of ram, the two rotors shear, extrude, and stir rubber (plastic) materials at different rotational speed in the pressure-tight mixing chamber, and finish the process of mixing or plasticizing.

Features of Rubber Internal Mixer

1. Rubber or plastic stock can be plasticized or mixed in a closed and pressurized space with the temperature controlled so that the productivity is high and the quality is good and stable.

2. Optimization of the parameters such as the helical angle of rotor wings and the wing overlap length brings about even distribution of the stock.

3. All the parts in contact with stock are ground, plated with hard chrome and polished. The rotor wings are built up by welding with the abrasion-proof sintered carbide to resist abrasion and corrosion.

4. All the parts in contact with stock are of the jacket design where water/steam/medium oil is led through to provide cooling or heating and can meet different requirements for the rubber or plastic mixing process.

5. Stock is fed through the rear door of the framework (or another port) and discharged by tilting the mixing chamber forward by 140°. Such a design makes it possible to arrange the up and down process in a line and facilitates stock color changing and the mixing chamber cleaning.

6. The standard tilting system of 75L~200L dispersion mixer adopts hydraulic driving, which is more stable and efficient. Worm and gear tilting system is adopted for 1L~55L models. It is optional according to customers’ different requirements.

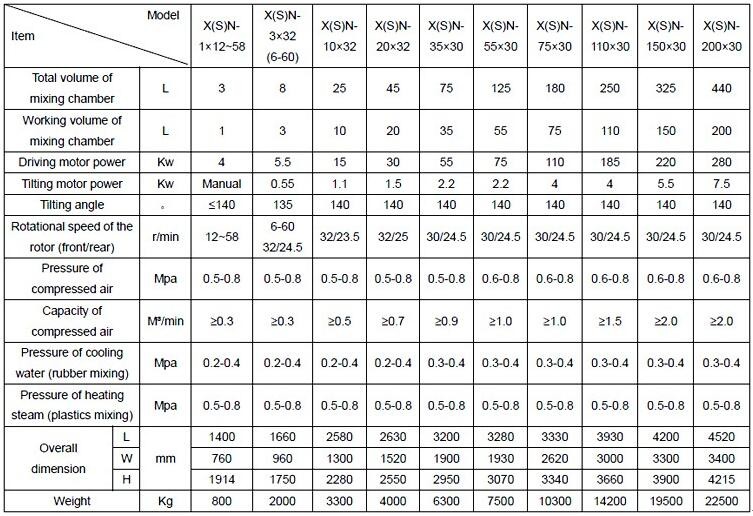

Main technical parameters:

110L banbury mixer(door drop type)

(Exported to Korea)

10L and 20L hydraulic tilting type rubber kneader

(Exported to Malaysia)

110L hydraulic tilting type rubber kneader

(Exported to Poland)

Foam plastics banbury mixer

(Exported to Turkey)

35L rubber kneader

(Exported to Sri Lanka)

55L rubber kneader

(Exported To Thailand )

75L rubber kneader

(Exported to Russia)

150L rubber kneader

(Exported to Brazil)

110L banbury mixer for reclaimed rubber desulfurizing

(Exported to Mexico)

Our packing way :Export standard (wooden package ) or according to your requirement.

Our Services :

1. We will design,manufacture,install and test the machines according to customers' requirement .Relevant personnel training for customers,ensure that customers fully grasp the use and maintenance of technology.

2. Our service department listen to customers' feedback at any time and provide spare parts timely.

Welcome to visit our factory and we can show you the machine in working condition:

If our products win your interest, please send us inquires and we will provide detailed information to you. We can also make non-standard machines according to your request.