RSBW25 Sprag односторонний подшипник задний стопорный

- Категории: Другие шарикоподшипники >>>

- Поставщик: Changzhou,Tianniu,Transmission,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Production Description

Description of One Way Sprag Type Freewheel Bearing Backstop Cam Clutch

Structure: RSBW one way Bearing Backstop Clutch is a sprag type freewheel. It is self-contained, centered by plain bearings for low rotational speeds, and sealed using shield protected 0-Rings.

Application: Primarily used as backstop ,this type provides a high torque capacity with a minimum space requirement. The design allows installation in difficult environments such as high humidity or water splash areas.

Package detail: radial spherical plain bearings are delivered grease lubricated, ready to install in a vertical or horizontal position.

| Model | RSBW25 |

| Torque(Nm) | 606 |

| Overrunning Speed(rpm) Inner Race | 400 |

| Inner Race Size(mm) | 25 |

| Outer Race Size(mm) | 106 |

| Thickness(mm) | 48 |

| Weight(Kg) | 2.6 |

Catalogue of One Way Sprag type Backstop Clutch Bearing RSBW Cam Clutch

Type | Size |

| Overrunning Speeds |

| Weight | |||||||

RSBW | dH7 | TKN1) | nimax | D | L 1 | F | E | B | N | L | bH11 |

|

[mm] | [Nm] | [min-1] | [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | [kg] | |

20 | 375 | 400 | 106 | 35 | 113 | 102.5 | 40 | 35 | 15 | 18 | 2 | |

25 | 606 | 400 | 106 | 48 | 113 | 102.5 | 40 | 35 | 15 | 18 | 2.6 | |

30 | 606 | 400 | 106 | 48 | 113 | 102.5 | 40 | 35 | 15 | 18 | 2.5 | |

35M | 375 | 400 | 106 | 35 | 113 | 102.5 | 40 | 35 | 15 | 18 | 2 | |

35 | 606 | 400 | 106 | 48 | 113 | 102.5 | 40 | 35 | 15 | 18 | 2.4 | |

40 | 1295 | 300 | 132 | 52 | 125 | 115 | 60 | 35 | 15 | 18 | 4.6 | |

45 | 1295 | 300 | 132 | 52 | 125 | 115 | 60 | 35 | 15 | 18 | 4.5 | |

50 | 1295 | 300 | 132 | 52 | 125 | 115 | 60 | 35 | 15 | 18 | 4.5 | |

55 | 1295 | 300 | 132 | 52 | 125 | 115 | 60 | 35 | 15 | 18 | 4.4 | |

60 | 2550 | 250 | 161 | 54 | 140 | 130 | 70 | 35 | 15 | 18 | 6.5 | |

70 | 2550 | 250 | 161 | 54 | 140 | 130 | 70 | 35 | 15 | 18 | 6.4 | |

80 | 4875 | 200 | 190 | 70 | 165 | 150 | 70 | 45 | 20 | 25 | 9.9 | |

90 | 4875 | 200 | 190 | 70 | 165 | 150 | 70 | 45 | 20 | 25 | 9.8 | |

Mounting Example

Application

Packaging&Shipping

Company Information

Certificate

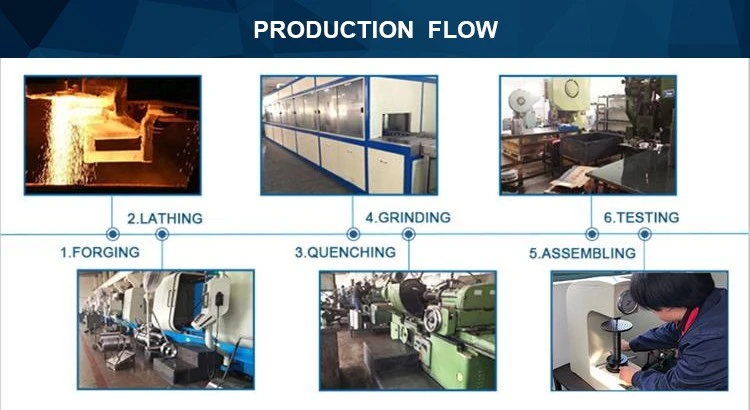

Production Process

FAQ