eva banbury kneader /rubber mixer/kneader rubber

- Категории: Internal Mixers >>>

- Поставщик: Qingdao,Jiuzhou,Jucai,Machine,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Rubber Dispersion Kneader

working volume : 1.5L,3L,5L,10L,20L,25L,35L,55L,75L,95L,110L,150L,200L,300L

Front roller speed : 30 r/min ,32 r/min ,40 r/min

Tilting drive type : worm gear pair drive , hydraulic drive

Main drive type : Left hand drive , right hand drive

Heating / cooling type : steam heating / water cooling ,warm water circulating heating / cooling ,electri heating / water cooling,oil heating / cooling

Gearbox type : Medium carbon alloy steel mid hard teeth gearbox / low carbon alloy steel hard teeth gearbox

Product Application

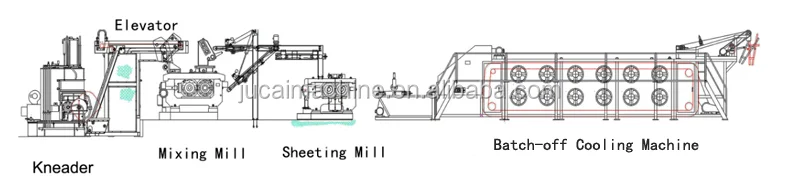

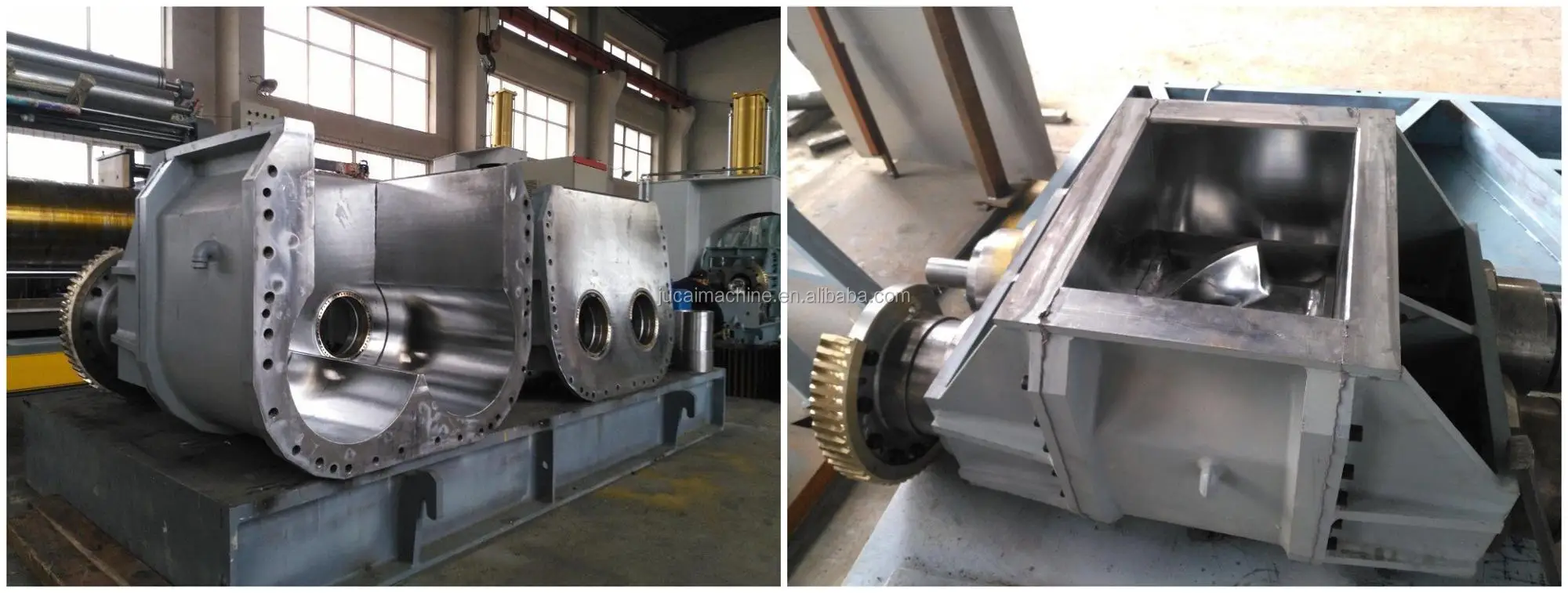

The series of rubber kneader machine is a type of dispersion kneader, consist of pneumatic control system, electric control system, tilting mechanism, mixing chamber, main driving system, dust sealing device, thermal resistance, rotor and cooling/heating system. You can choose the right model according to your needs. Below is the main technical parameters of the models

Machine feature

1. Pneumatic control system is controlled by PLC instruction . A bi-directional air cylinder make the ram up or down , in case thatoverload occurs in the mixing chamber ,the top ram can be raised automatically or manually if necessary , so as to protect motor from overload

2.Tilting mechanism consists of brake motor , cycloidal gear reducer , TP type worm and worm gear etc . It is able to actuate the mixing chamber to tilte by 140 around the front rotor

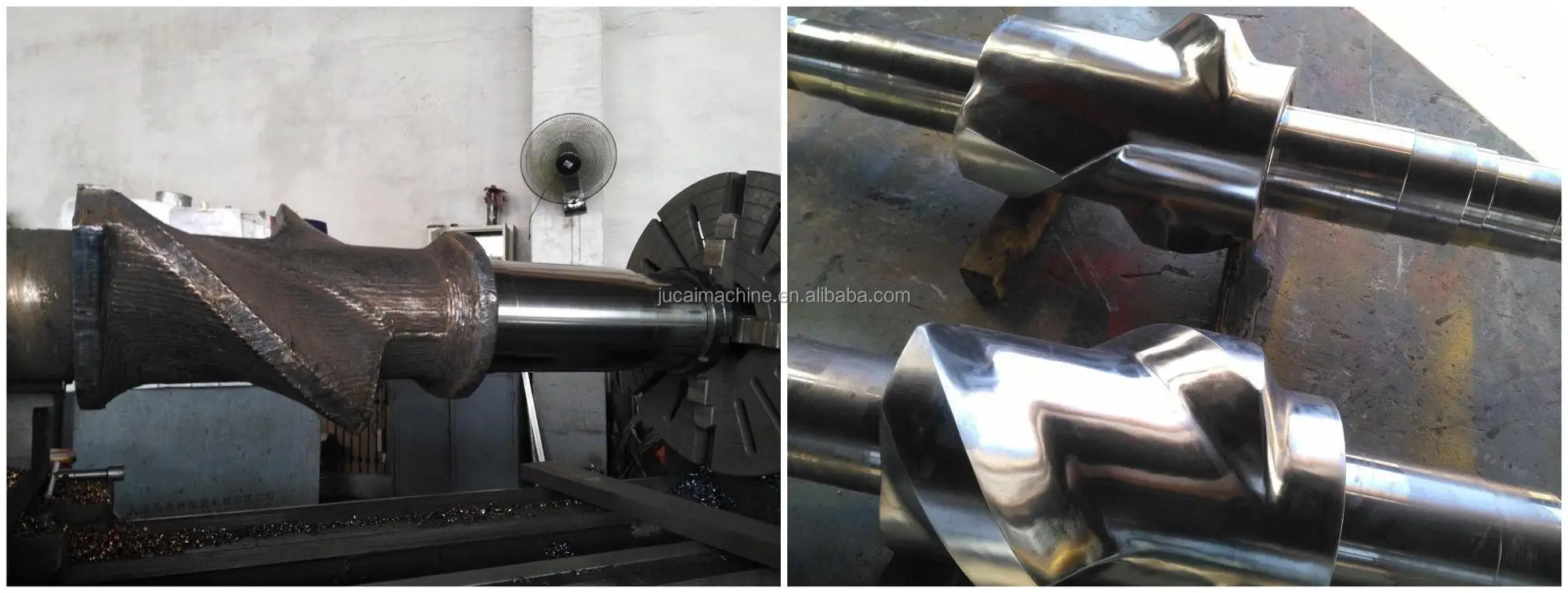

3.rotor shaft wing body top and wing corner are welded up with wear resistant alloy . rotor shaft surface ,the mixing chamber inner wall , upper ram surface and other surface connected with stock are hardened or polished and plated with hard chrome , or welded up wear resistant alloy welding , so they are wear resistant and corrosion resistant

4.rotor shaft is of integral structure rotor wing body welded on bored shaft , so it improves the strength and stiffness of the rotor . rotor inner wing vody cavity can be put through the cooling water or heating steam

5..mixing chamber is jacket type hollow structure . upper ram is hollow to increase cooling or heating area and the temperature control effect

6.main driving system consists of main motor ,reducer ,connecting gearbox odd-speed and face to face rotation of rotors is achived

7.electrical control system adopts the imported PLC device . All electronic components are imported or introduction technology products , to improve the reliability of the system.

model | X(S)N25*32 | X(S)N35*30 | X(S)N55*30 | X(S)N75*30 |

Total volume of chamber | 50L | 75L | 125L | 180L |

working volume of chamber | 25L | 35L | 55L | 180L |

main motor | 37 kw | 55kw | 75 kw | 110 kw |

tilting motor | 1.5 kw | 2.2 kw | 3.0 kw | 4.0 kw |

tilting angel | 135 | 140 | 140 | 140 |

rotor rotated speed | 32/25 | 30/24.5 | 30/24.5 | 30/24.5 |

pressure of compressed air | 0.6-0.8Mpa | 0.6-0.8Mpa | 0.6-0.8Mpa | 0.6-0.8Mpa |

cooling water pressure | 0.3-0.4 Mpa | 0.3-0.4 Mpa | 0.3-0.4 Mpa | 0.3-0.4 Mpa |

cooling water consumption | 6-10 | 8-12 | 10-15 | 18-20 |

machine weight | 4500 kg | 6500 kg | 7500 kg | 10300 kg |

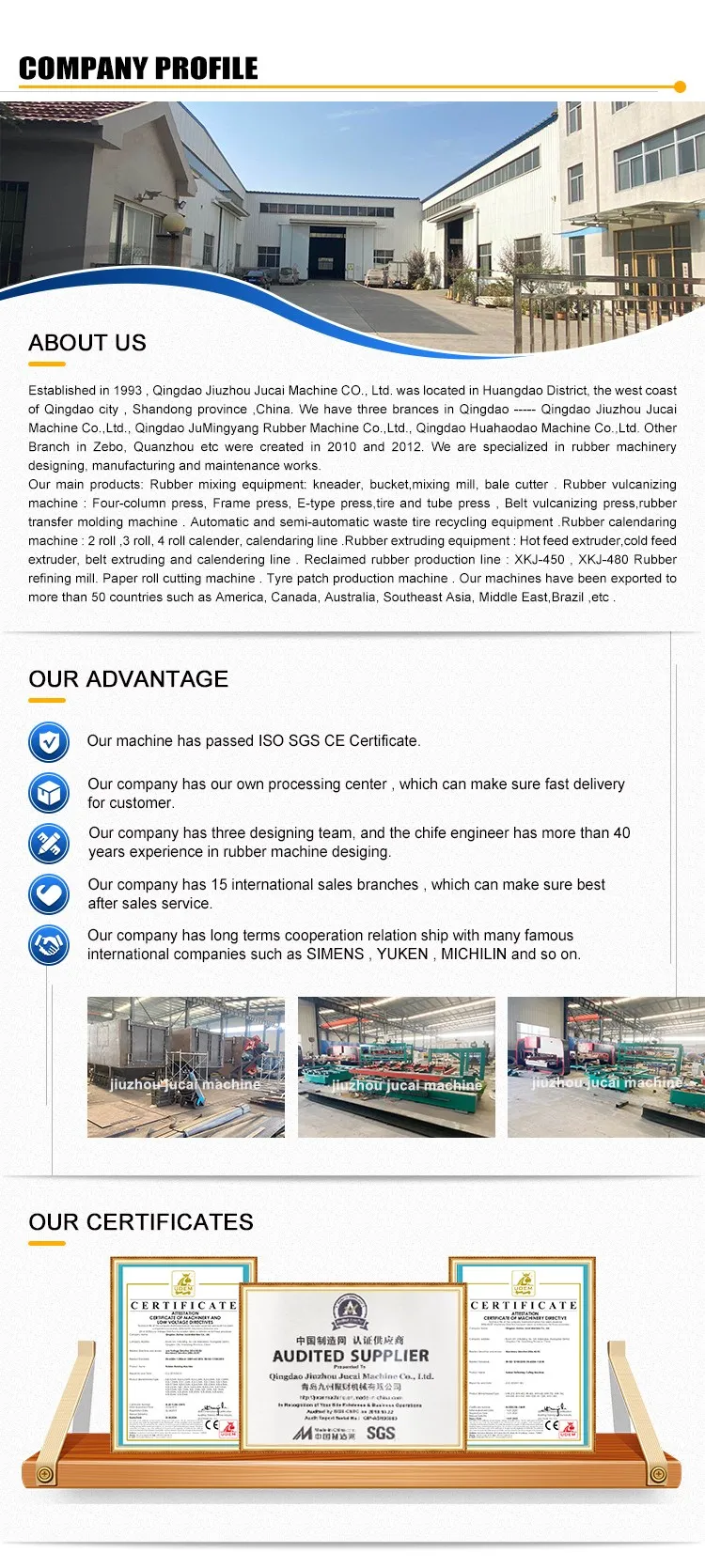

Factory + trade (integration), 30 years focusing on rubber machine design and production .

OEM is also acceptable for us.

2.How to choose the most suitable products?

Our professional team will give you the best suggestion as long as you tell us what kind of product you need to do and the required specification.

3.Do you accept customization service?

Yes, of course, we can not only offer standard machines, but also customized machines according to your request. Don’t hesitate to tell us your requirement, we will try our best to meet your needs.

4.How about your warranty?

Generally, our warranty is one year. Within the warranty period, we can offer technique support and part parts change,

necessarily, our engineers may go to your place for better service.

5.How about the packing for machine, is it safely protected during transportation?

Our machine is packed by standard export wooden box, it won’t be damaged. We’ve delivered many testing machines abroad by sea or by air without damage.

6.What is the order process?

Inquiry - quotation - communication - order confirming - deposit payment - production - testing and debugging - balance payment -packing - delivery - customer receiving - after service.