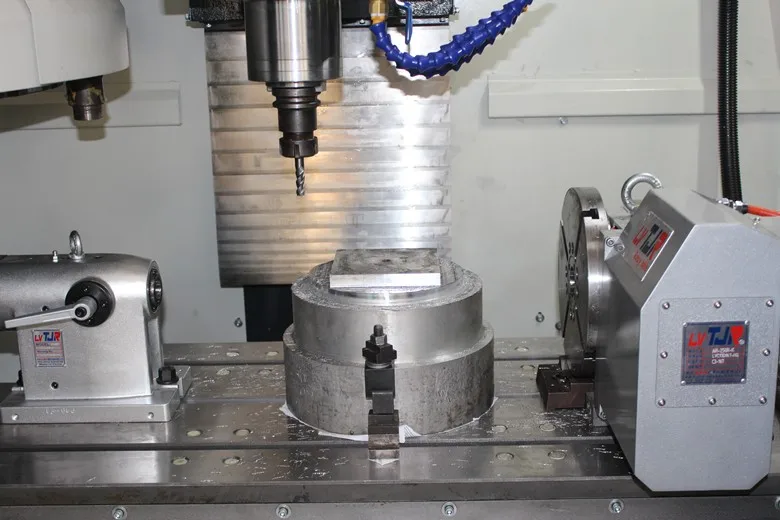

VMC850 3 оси вертикальный обрабатывающий центр с ЧПУ фрезерный

- Категории: Основные и запасные части машин >>>

- Поставщик: Taian,Yuzhuo,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Item | VMC850 CNC Machining Center | ||||

Travel | X axis | 800mm | |||

Y axis | 500mm | ||||

Z axis | 500mm | ||||

Spindle nose to table | 120-620mm | ||||

Spindle nose to column | 550mm | ||||

Feed | Max. X rapid feed | 24m/min | |||

Max. Y rapid feed | 24m/min | ||||

Max. Z rapid feed | 15m/min | ||||

Cutting feed | 1-10000mm/min | ||||

Torque | 10/10/15N.m | ||||

Table | Table size | 1000x500mm | |||

Max. load | 500kg | ||||

T slot | 5-18-90mm | ||||

Spindle | Type | Belt | |||

Speed | 50-8000rpm | ||||

Spindle bore | 120mm | ||||

Spindle taper | BT40 | ||||

Pull stud | MAS403-40BT-1 | ||||

Spindle motor synchronizing wheel | Taiwan | ||||

Spindle belt | Taiwan | ||||

Main motor | 7.5/11kw | ||||

Acuracy | Positioning Accuracy (JIS) | ±0.015/300mm | |||

Repeatibility (JIS) | ±0.0075mm | ||||

Machine | Size | 2650x2300x2450mm | |||

Weight | 5200kg | ||||

Main feature:

The feed axis machining center for X, Y, Z and 4th axis coordinate control, spindle servo motor powered,magazine capacity of 20. can achieve a variety of disc-type, plate type, shell, Cam, mold and other complex parts in a single setup, complete the drilling, milling and processing a variety of processes, boring, expanding, reaming, tapping,etc. suitable for many varieties, small batch production of complex, high-precision machining of parts to better show its superiority.

Standard Configuration

1)SYNTEC 21MA system

2)16T-Funnel type tool changer

3)Taiwan linear guide ways

4)Taiwan BT40/120/8000 spindle

5)full enclosure machine guard

6)automatic central lubrication system with alarm

7)spindle cooling unit

8)tool holder and pull stud

9)working lamp

Optional Configuration

1) FANUC 0i-MF/SIEMENS 808D system

2)Arm type tool changer

3)screw type chip conveyor

4)chip cart

5)4th or 5th axis

6)Metrol tool setters

7)transformer to suit local power supply

Pre-sale service :

After-sale service :

1.Warranty period is one year, life-long after sale service.

2.Engineers are available to service machinery overseas.

3.Over 18 years experience in the CNC Machine industry.

4.Our experienced technicians can offer you answer to your technical questions, and in many cases, solve your problem effectively over the phone.

Tai’an YuZhuo Machinery Co.,Ltd(as for “YZ CNC”),is a company including active and professional teams ,specialized in CNC machining Center,CNC Lathe Machine,Wheel Lathe machine . Our team have great experience on manufacturing and exporting. Our service department has experienced technicians that can offer you answers to your technical questions, and in many cases, solve your problem effectively over the phone. We are dedicated to provide customers with the best, highly value added machines. We have earned a strong reputation in design and manufacturing of a wide variety of CNC machine tools.

We continuously improve the performance level of our machines, strengthen our quality control system, and offer worldwide support services. Our dedication to the global marketplace will create a new era of CNC machine tools. Furthermore, we are serious about quality, customer input, and reacting to market demands. Our fully equipped quality control department performs the final inspection of the machine and in process inspection of parts. Our quality control personnel are well trained to conduct rigorous inspections by using precision, sophisticated instruments. We deeply believe that quality is the life of our company and customer service is the power that drives our company forward. We are also looking for cooperation with professional dealers in the world. This would make us to create a new opportunity in certain area and offer top service quality as we have in China.

Q: Is your company a factory or trading company?

A: Our company is a factory, doing international business for decades of years.

Q: Where is your factory located? How can I visit there?

A: Our factory is located in Taian City, ShanDong Province, China with convenient transportation by flight, train, and bus. All our customers, are warmly welcome to visit our company.

Q: How does your factory do on quality control?

A: Quality is our culture.We pay much attention to quality controlling from the environmental-friendly raw material,skilled workers to advanced testing equipment.

Q: How about your service?

A: we can provide 24hours online service, provide local free training. all parts free charge change in 3 years.

VMC,Vertical CNC Machining center Centro de mecanizado CNC vertical,Vertical CNC Milling Machine Fresadora CNC vertical, 3 axis CNC milling machine , Fresadora CNC de 3 ejes,Metal CNC Milling Machine CNC Machining center Fresadora CNC de metal Centro de mecanizado CNC, 3 axis 4 axis 5 axis CNC Machining center 3 ejes 4 ejes 5 ejes CNC Centro de mecanizado,High precision Low Price CNC Machining center , Centro de mecanizado CNC de alta precisión y bajo precio,high speed cnc milling machine, milling machine for sale, mill machinery manufacturer,