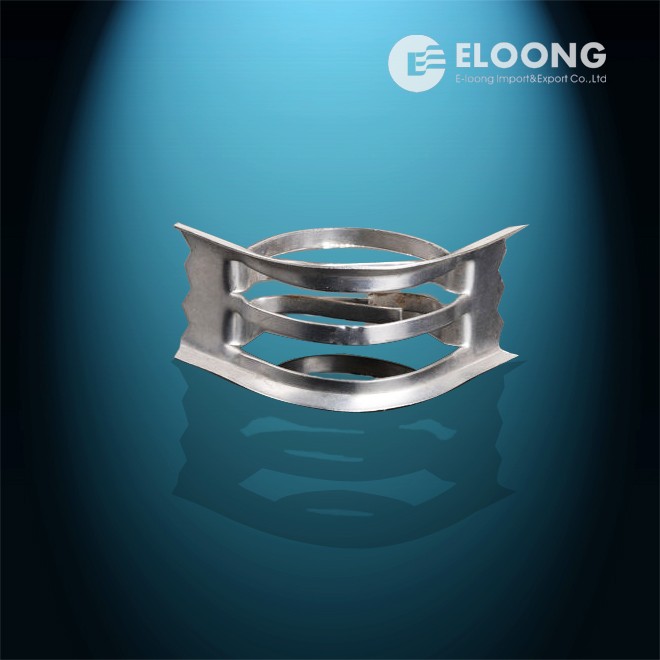

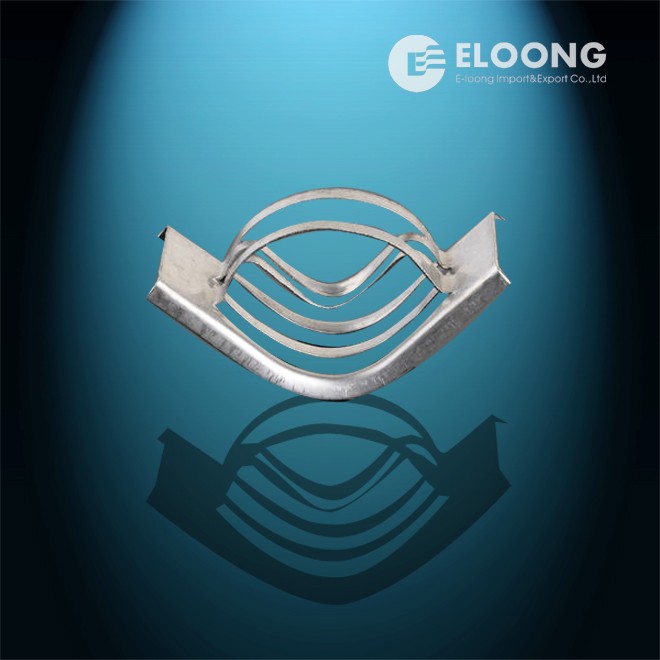

Металлическое седловое

- Категории: Части химического оборудования >>>

- Поставщик: Jiangxi,Eloong,Environmental,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Metal Intalox Saddle

Metal intalox saddle is made of materials like carbon steel, stainless steel or Aluminum alloy, etc.

The product has features such as thin wall, heat resistant, high free volume, high capacity, low resistance, high separation efficiency and so on.

It is especially suitable for rectification towers under vacuum to treat thermosensitive, decomposable, polymerizable or cokable systems, so it is widely used in packing towers in petrochemical industry, chemical fertilizer industry and environmental protection, etc.

Features:

MSRs offer a 30% lower pressure drop than Pall Rings but with a lower liquid hold-up. This facilitates shorter packed bed heights. MSRs’ physical shape permits maximum randomness and minimum alignment, Advanced design gives it a high rate of liquid film surface renewal producing a high mass transfer rate, leading to a greater capacity and efficiency compared to other random packings, Large number of contact points for homogenous distribution of liquid and gas, Facilitates shorter packed bed heights.

Technical data

Refer to HG/T21554.2-95

Size mm | Surface m2/m3 | Free volume % | Number Pieces/m3 | Weight Kg/m3 |

|---|---|---|---|---|

| 25×15×0.3 | 171 | 96.7 | 87720 | 161 |

| 38×16.5×0.4 | 123 | 97.8 | 38160 | 155 |

| 50×29×0.5 | 79 | 98.2 | 11310 | 129 |

| 76×35.5×0.8 | 55 | 97 | 4250 | 112 |

Application:

Metal Saddle Rings offer high performance random packing, successfully used in mass transfer towers both small and large diameter. Metal Saddle Rings are also frequently used in deep vacuum towers where low pressure drop is crucial and also high pressure towers where capacity significantly exceeds conventional trays.

1) A versatile packing used in distillation, absorption etc.

2) Used in both deep vacuum and high pressure towers.

Material available:

Carbon Steel, Stainless Steel, Monel, Titanium, Aluminum and many other High Alloy and Duplex specialty metals.