Гомогенизатор с высоким сдвигом для косметики крем тела машина смешивания масла лосьона эмульгатор

- Категории: Mixing Equipment >>>

- Поставщик: Guangzhou,Jinfeng,Light,Industry,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

High shear homogenizer for cosmetic body cream butter lotion mixing machine emulsifier mixer

Product Introduction

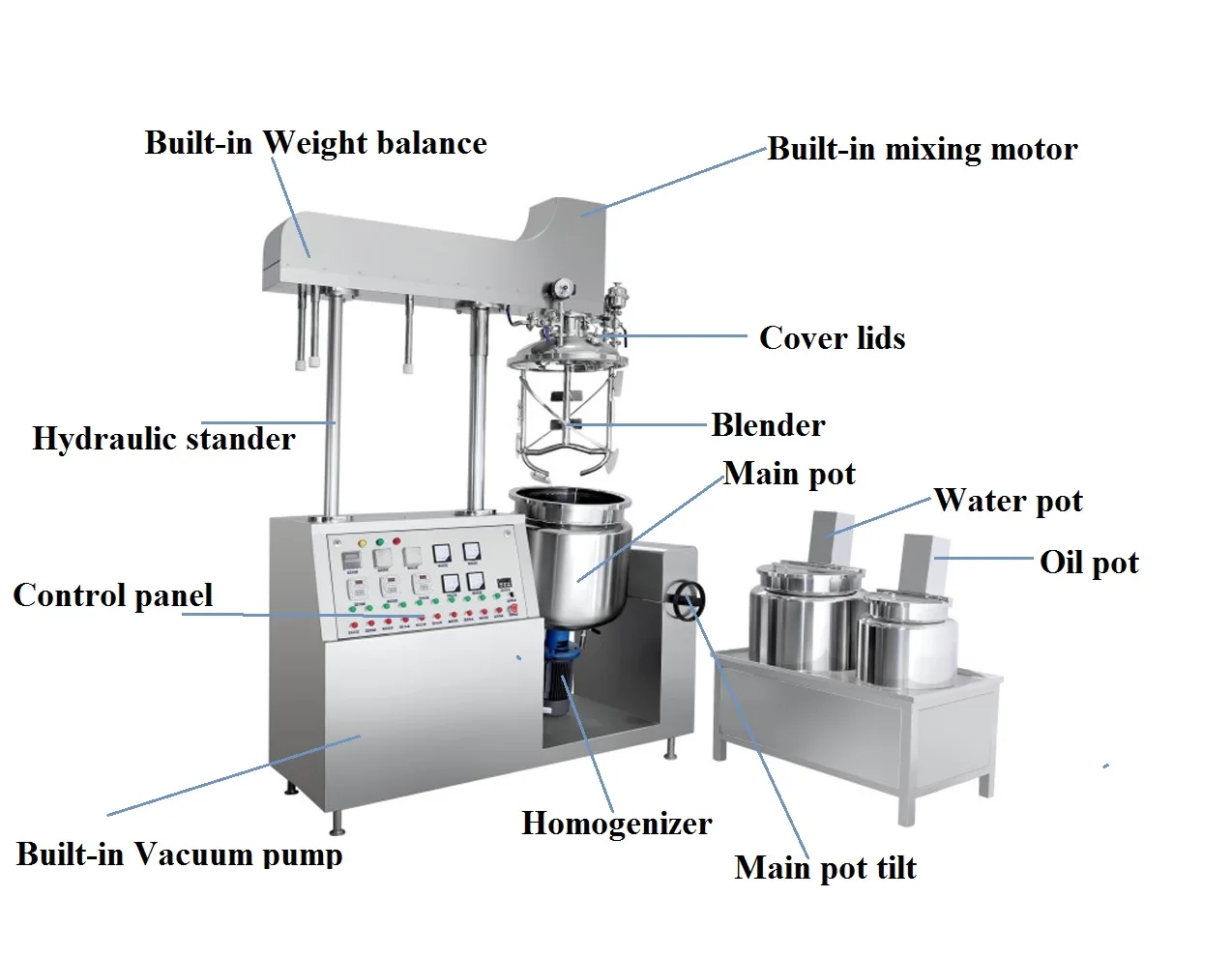

This equipment is a set of vacuum deaeration, mixing, homogenizing, heating, electric control and other functions in one, equipment is composed by the vacuum homogenizing emulsifying pot, vacuum system, a lifting system, oil and water pot. Can be used in cosmetic cream, ointment, honey, paste production

What cream will you get after used our high shear homogenizer?

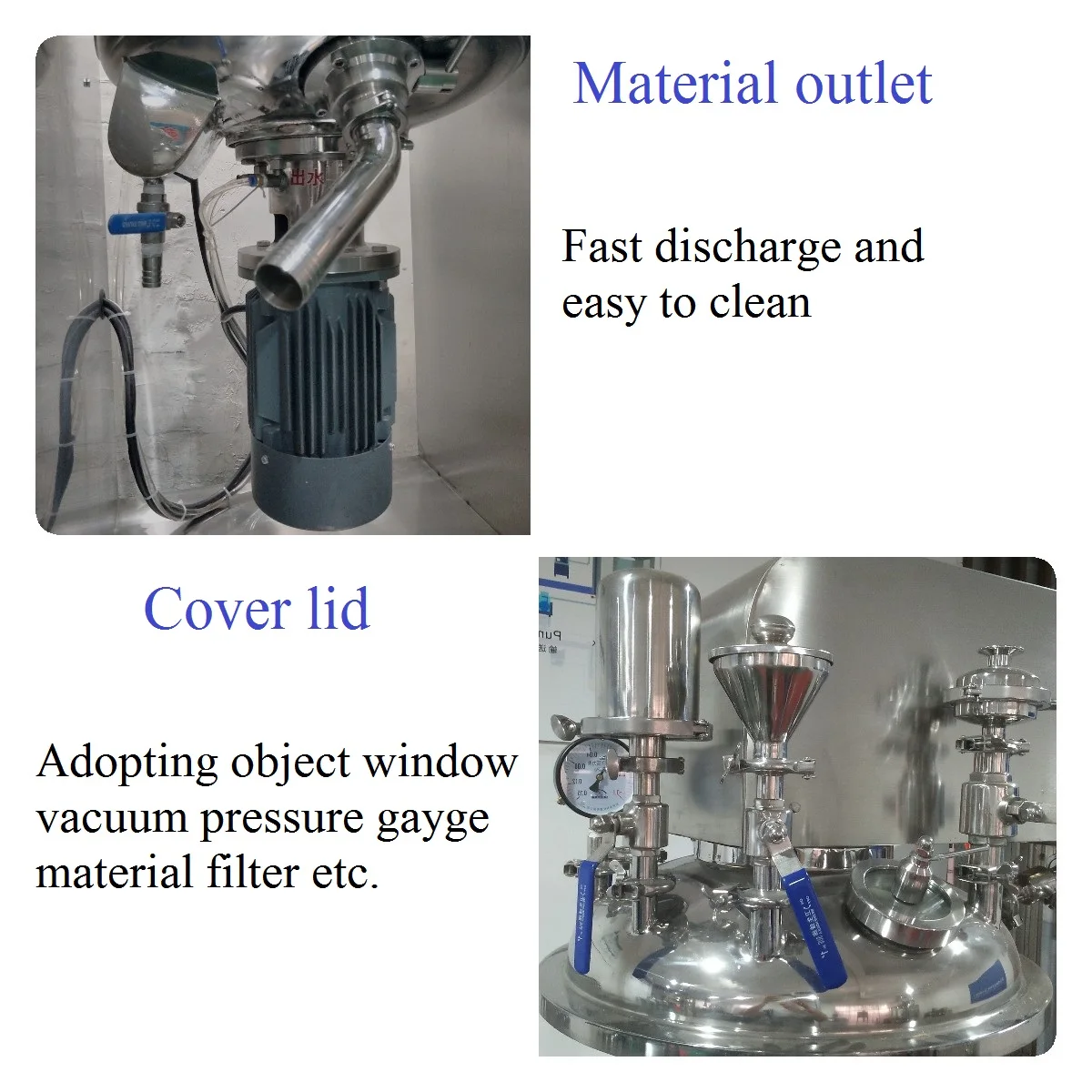

Detail Pictures

Drawing

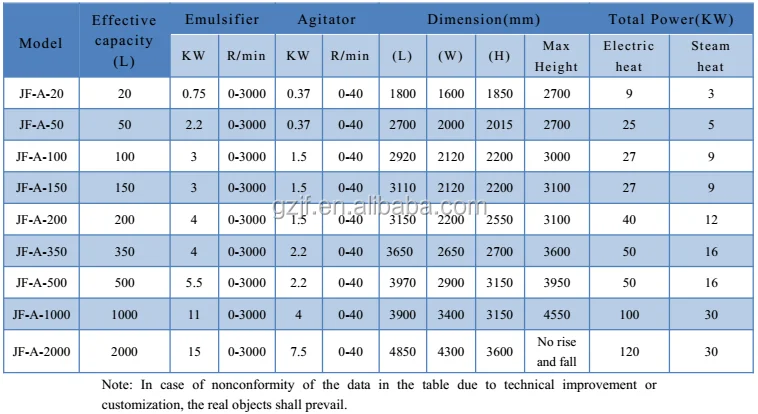

Technical parameters

Sample

| 1. Package: PE film cover inside and then plywood case. |

| 2. Accept terms: EXW, FOB, C&F, CIF, etc. |

| 3. Shipping by Express, Air or Sea based on customers' requirements and lowest cost solution. |

Terms & Conditions:

Payment: T/T 30% in advance, balance paid before shipment,video inspection or person inspection before shipment

Delivery: 25-30 days after receiving the deposit.

Packing: wooden case

Validity: 1year

Sales After Service:

Guaranty: One Year

One set of consumable accessories will be provided with the machine.

Before delivery, we will adjust the machine to fit for your product.

Any question, you can mail/call us at any time. And our most experienced engineers is assigned to give consulting service, and always available for dispatching abroad.

All spare parts are always available for delivery

Manual is in English.

Installation/ Training:

The installation can be provided by theJINFENG Company. It must be after shipment and machine has arrived and factory must be ready equipped with all necessary requirements before booking installation with JINFENG Company. Our engineers will come to the site for the complete and final installation. During the installation session, a one day training course will be provided to the customer for operation and maintenance procedure. The purchase at US$80-100/person/day plus all local transportation, accommodation, air tickets (round trip). Day charges include travel day.

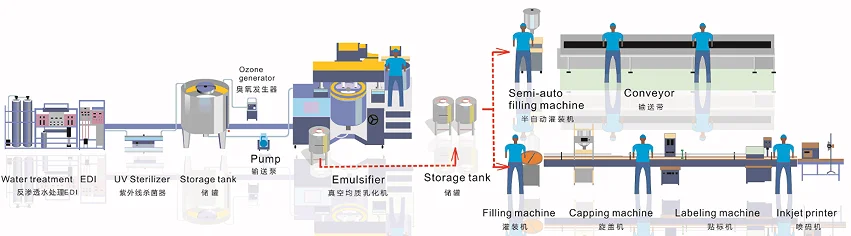

Full production line for cream(for your reference)

Semi-automatic production line,

Water treatment → EDI,ultraviolet(alternative) → water tank → Ozone generator,pump(alternative)→ homogenizer emulsifier → material tank → semi-automatic filling machine → semi-automatic capping machine → semi-automatic labeling machine → inject printer → conveyor(alternative)

Automatic production line,

Water treatment → EDI,ultraviolet(alternative) → water tank → Ozone generator,pump(alternative)→ homogenizer emulsifier → material tank → automatic filling and capping machine → automatic labeling machine → inject printer