Автоматический небольшой лабораторный смеситель для порошковых смесителей промышленный пищевой химический порошок смесительное

- Категории: Mixing Equipment >>>

- Поставщик: SINOPED,TECHNOLOGY,(SHANGHAI),CO.,LTD

Поделиться:

Описание и отзывы

Характеристики

Product Description

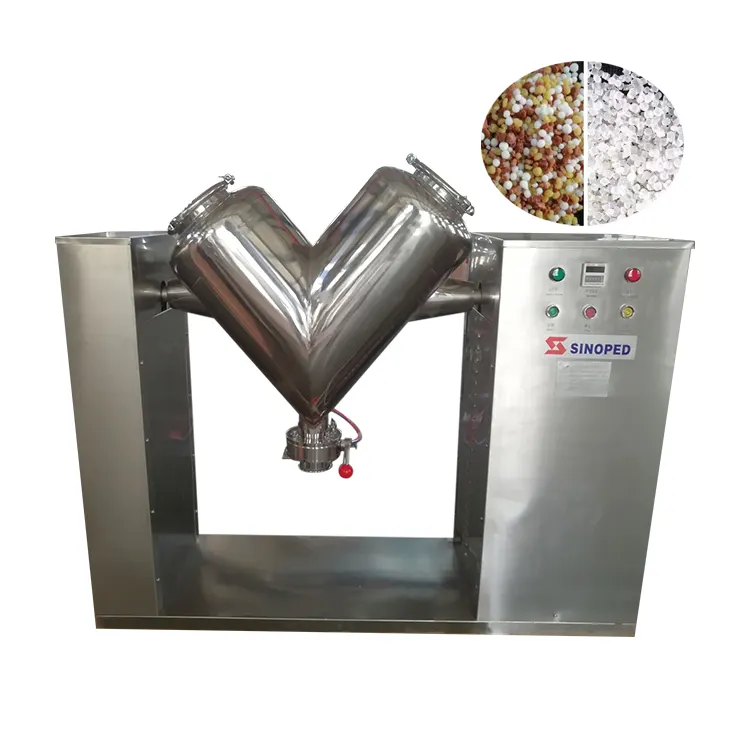

V type multifunctional mixer

This machine is suitable for mixing dry powder or granular raw materials such as chemicals, food, etc.

This machine has a unique structure, high mixing efficiency, no dead angle, and is made of stainless steel. The inner and outer walls are polished, with beautiful appearance and uniform mixing. The scope of application is wide. It can also be equipped with a forced agitator according to user requirements to meet the raw material requirements of very fine powder, cake and certain wet materials. One end of the machine is equipped with a motor and a reducer. The power of the motor is transmitted to the reducer through the belt, and the reducer is transmitted to the V-shaped barrel through the coupling. Make the V-shaped barrel run continuously, and drive the materials in the barrel to mix up, down, left, and right in the barrel.

This machine has a unique structure, high mixing efficiency, no dead angle, and is made of stainless steel. The inner and outer walls are polished, with beautiful appearance and uniform mixing. The scope of application is wide. It can also be equipped with a forced agitator according to user requirements to meet the raw material requirements of very fine powder, cake and certain wet materials. One end of the machine is equipped with a motor and a reducer. The power of the motor is transmitted to the reducer through the belt, and the reducer is transmitted to the V-shaped barrel through the coupling. Make the V-shaped barrel run continuously, and drive the materials in the barrel to mix up, down, left, and right in the barrel.

Main structural features:

This machine adopts manual feeding and closed baffle valve for discharging. It does not generate powder dust, nor does it cause mechanical compression and strong friction when mixing. So material particles can remain intact. The mixing barrel is made of stainless steel, which does not pollute the material. In addition, this machine has a timing device, which can control the mixing time of the material.

Machine video

Technical Parameters

Model | VH-20 | VH-30 | VH-50 |

Volume | 20L | 30L | 50L |

Barrel diameter | 220mm | 220mm | 304mm |

Feeding inlet diameter | 133mm | 133mm | 150mm |

Discharging outlet diameter | 75mm | 75mm | 80mm |

Best loading | 5.6KG | 8.4KG | 14KG |

Max. loading | 8KG | 12KG | 20KG |

Barrel rotating speed | 20r/min | 20r/min | 20r/min |

Power | 0.55KW | 0.55KW | 0.75KW |

Dimension | 1095*340*885mm | 1280*360*1055mm | 1350*450*1160mm |

Warranty | 1 year | 1 year | 1 year |

Don't Worry! We have several Models. We can recommend you according to your requirement.

Main Application

Main uses of mixer

This machine is mainly used for the uniform mixing of powder, granular and other materials in various industries.

Wide range of applications

The machine is fully sealed and dust- free operation be in line with the dust- free processing requirements.Used in the chemical, foodstuffs industries and scientific research units.

The machine is fully sealed and dust- free operation be in line with the dust- free processing requirements.Used in the chemical, foodstuffs industries and scientific research units.

Machine Details

Working Principles

The reducing mechanism drives the barrel rotary, and the length of two barrels is different, which will produce asymmetry. And then the machine take advantage of this asymmetry for mixing materials. When the machine is running, materials from the decomposition to the combination, as potential energy differences, which will produce lateral force to promote the horizontal exchange of materials; and materials from the combination to the decomposition, as materials plane differences, which will produce lateral force to promote the horizontal exchange of materials again. The barrels rotary one cycle, which will make 25% of materials flow from one barrel to the other one; at the same time the materials will also produce radial flow, and then the materials can horizontally and radially decompose, alternating combination, so that the materials can mix evenly.

Operation and Maintenance

1. Connect the power first, setting the required mixing time, then turn on the switch, the machine

begin running.

2. After the mixing, if you found that the position of discharging port is not the best position, you should turn off the power first, and adjust the position of discharging port.

3. Before you use the machine, you should check the appliance,if it is normal; and check the covers of mixing barrels, if the covers are tightly closed.

4. User should clean the machine after the finish of work, especially the barrels, prevent the residual materials.

5. Note that the reducer should be added enough lubricating oil(generally use the 30 # machine oil), and the transmission should be added grease lubricant.

6. Users should maintain the machine once each half of year, change the lubricating oil of reducer, check if the appliance is aging, the appliance should be replaced if it is aging.

7. After you have been using the machine for one year or more, you should make a big maintenance, check the gab between each parts, and appropriately adjust them, so that the machine can keep in good condition.

1. Connect the power first, setting the required mixing time, then turn on the switch, the machine

begin running.

2. After the mixing, if you found that the position of discharging port is not the best position, you should turn off the power first, and adjust the position of discharging port.

3. Before you use the machine, you should check the appliance,if it is normal; and check the covers of mixing barrels, if the covers are tightly closed.

4. User should clean the machine after the finish of work, especially the barrels, prevent the residual materials.

5. Note that the reducer should be added enough lubricating oil(generally use the 30 # machine oil), and the transmission should be added grease lubricant.

6. Users should maintain the machine once each half of year, change the lubricating oil of reducer, check if the appliance is aging, the appliance should be replaced if it is aging.

7. After you have been using the machine for one year or more, you should make a big maintenance, check the gab between each parts, and appropriately adjust them, so that the machine can keep in good condition.

Machine Photos

FAQ

1. Do you have any installation team for installing and debug in my country ?

Yes, we have almost 20 agent&customer from different countries, all of them able to supply after sale service.

3. Are you a factory or a trading company?

4. What's your payment way?

5. How can you ensure the machine's quality after we put the order?

6. We are afraid you won't deliver us the machine after we pay you the money.

Please note our above business license and certificates. And if you don't trust us, you can use Alibaba's trade assurance serviceor .

Yes, we have almost 20 agent&customer from different countries, all of them able to supply after sale service.

2.Can your machine meet our need well?

We supply you a proposal as to your specific requst, each machine is customized to satisfy customer's need well.

We supply you a proposal as to your specific requst, each machine is customized to satisfy customer's need well.

3. Are you a factory or a trading company?

We are the manufacturer, and have been in industry for more than ten years.

4. What's your payment way?

T/T by our bank account directly, or by Alibaba's trade assurance service, or by the West Union, or in cash.

5. How can you ensure the machine's quality after we put the order?

Before the delivery, we will send you machine's pictures and videos, or you can come to us to have the quality checking by yourself, or by the third party inspection organization contacted by your side.

6. We are afraid you won't deliver us the machine after we pay you the money.

Please note our above business license and certificates. And if you don't trust us, you can use Alibaba's trade assurance serviceor .