Горячая Распродажа Экологически чистая Вращающаяся печь каолина низкая цена инвестиционная небольшая емкость латеритовая никелевая рудная для

- Категории: Cement Making Machinery >>>

- Поставщик: Shanghai,Yingyong,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Product Description

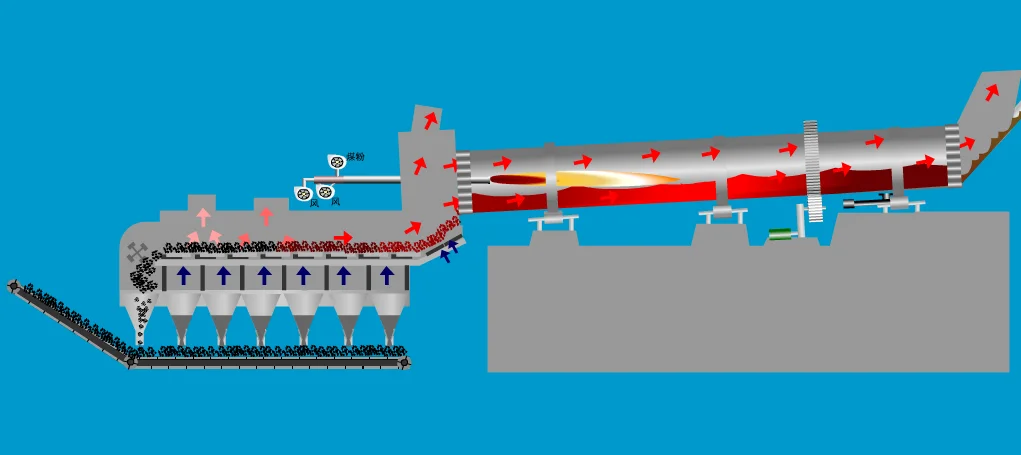

Laterite nickel ore smelting process for nickel-iron reduction, the main raw material is laterite nickel ore, reducing agent using cheap coal, peat, coal can be, the process steps are mainly material preheating treatment, reduction melting process, separation and refining three steps. When the equipment is running, the main drive motor transmits power to the open gear device through the main reducer to drive the kiln to rotate, and laterite nickel ore is calcined in the rotary kiln from the kiln tail. Due to the tilting and slow rotation of the cylinder, the material both rolls in the circumferential direction and moves in the axial direction to continue its process. Then, the generated clinker enters the cooler for cooling through the kiln head. The fuel is sprayed into the kiln from the kiln head, and the waste gas generated by combustion is exchanged with the material and exported from the kiln tail.

Product name | rotary kiln |

Type | Rotary |

Warranty | 1 Year |

Power | Customized |

Working principle

(1)The material is mainly crushed and ground by the weight of the grinding roller and the pressure of the pressing device. During the grinding process, the material is always subjected to the pressure of the grinding roller, and the grinding roller and the grinding table are not purely rolling, and the material is subjected to multi-direction force, thus improving the grinding capacity and grinding efficiency of the mill;

(2)When the material enters the mill, it is in full contact with the hot air, it is pulverized and floated in the hot gas, and the heat can be fully exchanged. The material is also dried while being ground;

(3)The grinding pressure of the grinding roller is provided by the hydraulic system, and is applied to the material through the pressing device and the transmission device to the grinding roller. By adjusting the pressure of the hydraulic system, the grinding pressure is changed to meet the different grinding requirements for different hardness materials;

(4)In order to avoid the violent vibration caused by the direct contact between the grinding roller and the grinding table during the empty working of the mill, there should be a certain gap between the grinding roller and the grinding table. Therefore, a limit device for controlling the gap size is specially designed, and the thickness of the material under the grinding roller can be known at any time by the limiting device, thus ensuring that the grinding machine operates under safe and economical working conditions;

Production Capacity

Main Product

Company Profie

Our Business

Custom Visiting

FAQ