50/100/150/200 TPD вращающаяся лаймовая печь для никелевой руды минеральных продуктов обжига

- Категории: Cement Making Machinery >>>

- Поставщик: Henan,Hongke,Heavy,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

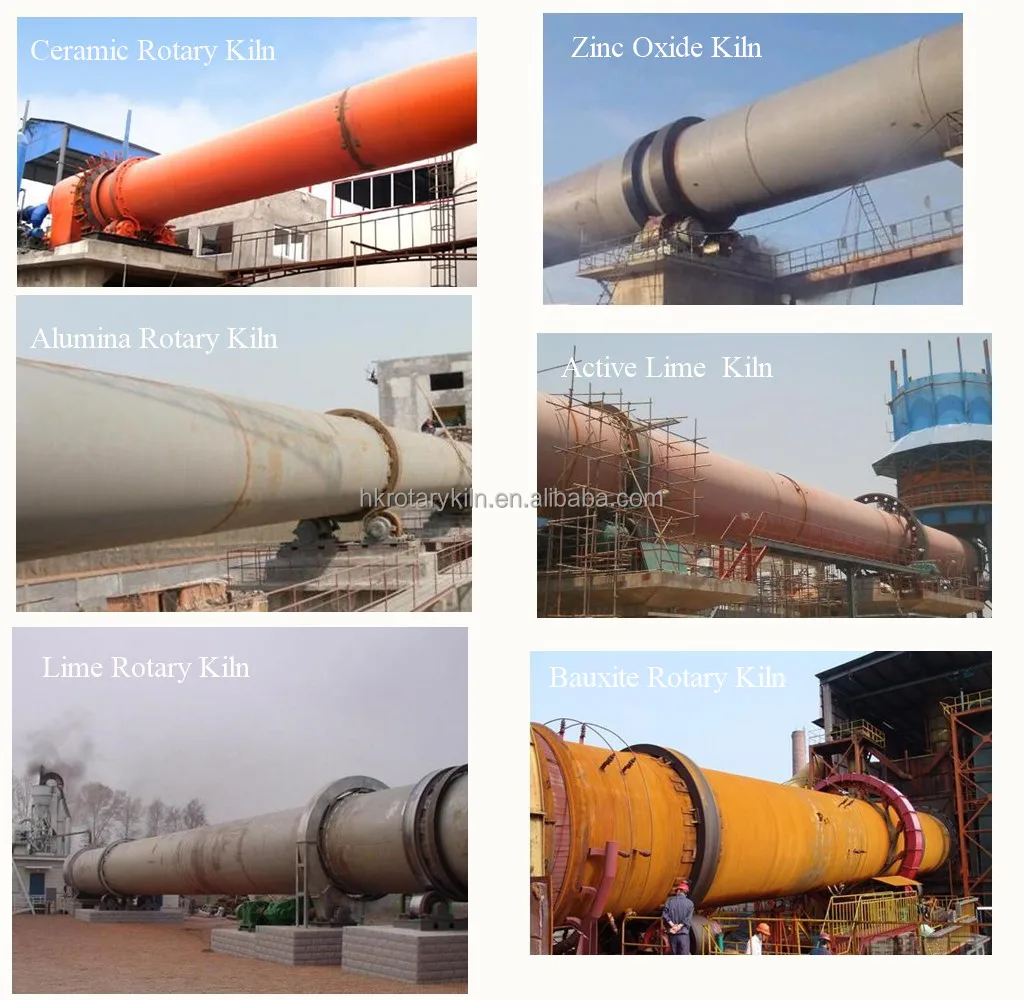

50/100/150/200 TPD Rotary Lime Kilns Nickel Ore Rotary Kiln for Mineral Products Rotary Kiln for Bauxite Calcination

Product Overview

In the world, 85% of bauxite is used to produce aluminum oxide, and about 10% of bauxite is used to

produce non-metallic aluminum.

The clinker calcined in rotary kiln for bauxite calcination is gray, light yellow and dark gray. It is mainly used for high alumina refractories and also for making fused brown corundum.

Rotary kiln light burning bauxite, also known as light burning powder, is the water purification agent polyaluminum chloride raw materials. White or grayish white, brownish yellow or light red due to iron. Density 3.9g / cm ~ 3, hardness 1 ~ 3, opaque, brittle. Ceramic, water purifier and so on need Al2O3 content 40%.

produce non-metallic aluminum.

The clinker calcined in rotary kiln for bauxite calcination is gray, light yellow and dark gray. It is mainly used for high alumina refractories and also for making fused brown corundum.

Rotary kiln light burning bauxite, also known as light burning powder, is the water purification agent polyaluminum chloride raw materials. White or grayish white, brownish yellow or light red due to iron. Density 3.9g / cm ~ 3, hardness 1 ~ 3, opaque, brittle. Ceramic, water purifier and so on need Al2O3 content 40%.

PROCESS PROCESS

The change of rotary Kiln for Bauxite Calcination can be divided into three stages: decomposition stage, secondary mullite stage and crystallization and sintering stage.

PRODUCT SPECIFICATIONS

Specification Model (mm) | The size of the kiln | Yield (t/h) | Speed (r/min) | Electrical power (kw) | Weight (t) | Remarks | ||||

Diameter (m) | Length (m) | Gradient (%) | ||||||||

φ1.4×33 | 1.4 | 33 | 3 | 0.9-1.3 | 0.39-3.96 | 18.5 | 47.5 | ---- | ||

φ1.6×36 | 1.6 | 36 | 4 | 1.2-1.9 | 0.26-2.63 | 22 | 52 | ---- | ||

φ1.8×45 | 1.8 | 45 | 4 | 1.9-2.4 | 0.16-1.62 | 30 | 78.2 | ---- | ||

φ1.9×39 | 1.9 | 39 | 4 | 1.65-3 | 0.29-2.93 | 30 | 77.59 | ---- | ||

φ2.0×40 | 2 | 40 | 3 | 2.5-4 | 0.23-2.26 | 37 | 119.1 | ---- | ||

φ2.2×45 | 2.2 | 45 | 3.5 | 3.4-5.4 | 0.21-2.44 | 45 | 128.3 | ---- | ||

φ2.5×40 | 2.5 | 40 | 3.5 | 9.0-10.5 | 0.44-2.44 | 55 | 149.61 | ---- | ||

φ2.5×50 | 2.5 | 50 | 3 | 6.25-7.4 | 0.62-1.86 | 55 | 187.37 | ---- | ||

φ2.5×54 | 2.5 | 54 | 3.5 | 6.9-8.5 | 0.48-1.45 | 55 | 196.29 | ---- | ||

φ2.7×42 | 2.7 | 42 | 3.5 | 10.0-11.0 | 0.10-1.52 | 55 | 198.5 | ---- | ||

φ2.8×44 | 2.8 | 44 | 3.5 | 12.5-13.5 | 0.437-2.18 | 55 | 201.58 | Preheater kiln | ||

φ3.0×45 | 3 | 45 | 3.5 | 12.8-14.5 | 0.5-2.47 | 75 | 210.94 | ---- | ||

φ3.0×48 | 3 | 48 | 3.5 | 25.6-29.3 | 0.6-3.48 | 100 | 237 | |||

φ3.0×60 | 3 | 60 | 3.5 | 12.3-14.1 | 0.3-2 | 100 | 310 | ---- | ||

φ3.2×50 | 3.2 | 50 | 4 | 40.5-42 | 0.6-3 | 125 | 278 | |||

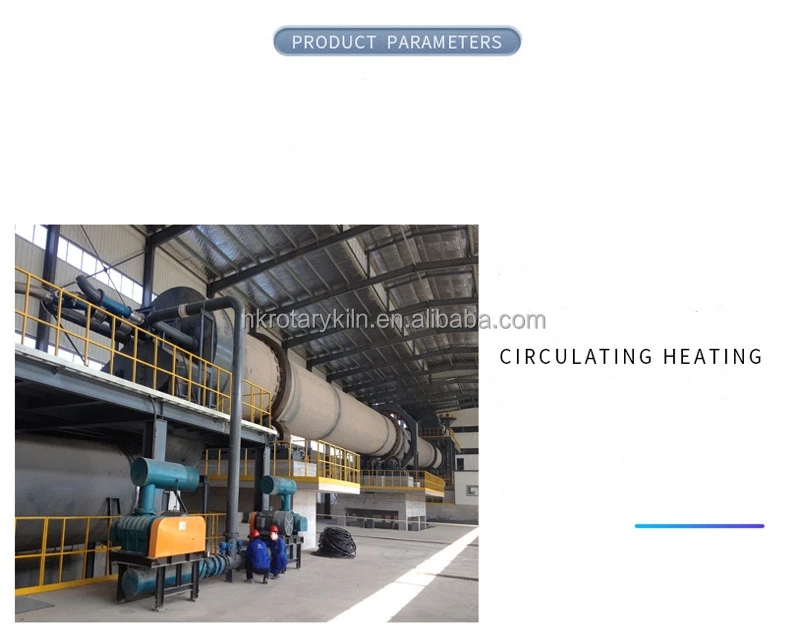

FEATURES AT A GLANCE

The combustion temperature, combustion atmosphere and combustion time can be adjusted and controlled flexibly to better adapt to the technological requirements

Rotary Kiln for Bauxite Calcination has the advantages of uniform heating of materials, full reaction, good product, good quality, stable and reliable operation of equipment, high adjustability and simple operation and maintenance.

Successful Project

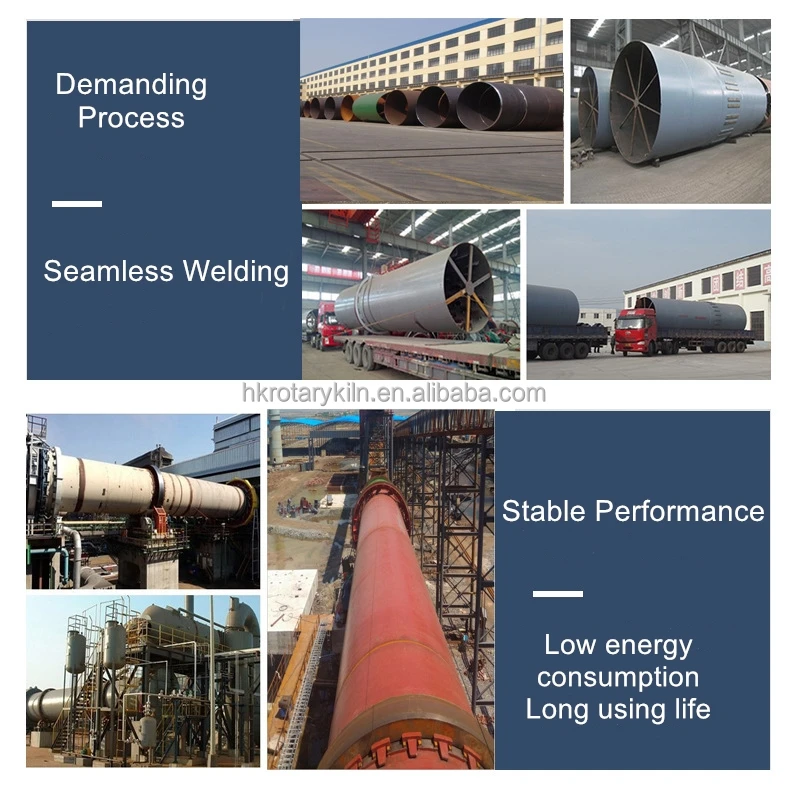

Factory Workshop Pictures

COMPANY PROFILE

Henan Hongke Heavy Machinery Co., Ltd. is located in Henan Province which is the cultural base of the central area of China. We are a mining machinery manufacturing enterprise that integrates scientific research, production and marketing.

We are a high-tech enterprise that specializes in the research and production of rotary kilns, dryers, crushers and so on, such as new type of lime rotary kiln, ceramsite kiln, zinc oxide rotary kiln, sludge rotary kiln, chemical rotary kiln, metallurgical

rotary kiln, Raymond mill, ultra-fine mill, large and medium dryer, ball mill, sand mill,stone production line, mineral processing equipment and so on.

From the design, production, installation and debugging, we provide you the entire tracking service.We adhere to the aim of high quality to survive, good credibility to make development, and sincerely look forward to cooperating with you!

We are a high-tech enterprise that specializes in the research and production of rotary kilns, dryers, crushers and so on, such as new type of lime rotary kiln, ceramsite kiln, zinc oxide rotary kiln, sludge rotary kiln, chemical rotary kiln, metallurgical

rotary kiln, Raymond mill, ultra-fine mill, large and medium dryer, ball mill, sand mill,stone production line, mineral processing equipment and so on.

From the design, production, installation and debugging, we provide you the entire tracking service.We adhere to the aim of high quality to survive, good credibility to make development, and sincerely look forward to cooperating with you!

FAQ

1. What is the minium order quantity?

One set.

2.How long is the warranty period?

One year. Wearing parts are excluded.

3. What is the after-service of your company?

We can provide the customers foudation drawing, installation service, work training as well as other service according to the

customer's requirements.

4.How long is the delivery time?

About 15 days after we receive the payment.

5. What are the payment terms?

T/T, L/C are the best, it can be adjustable according to different situations.

--------------------------------------------------------------------------------------

Kindly Note:

1. Please pay attention to the capacity. It's what you must take into consideration in choosing a suitable machine.

2. Please Inform us the follow figures:

1). Size and content analysis of raw material

2). Capacity ( t/h)

3). Heating Source ( Coal, natural gas or oil)

Upon we got your message we shall give you our favorable offer in short time.

One set.

2.How long is the warranty period?

One year. Wearing parts are excluded.

3. What is the after-service of your company?

We can provide the customers foudation drawing, installation service, work training as well as other service according to the

customer's requirements.

4.How long is the delivery time?

About 15 days after we receive the payment.

5. What are the payment terms?

T/T, L/C are the best, it can be adjustable according to different situations.

--------------------------------------------------------------------------------------

Kindly Note:

1. Please pay attention to the capacity. It's what you must take into consideration in choosing a suitable machine.

2. Please Inform us the follow figures:

1). Size and content analysis of raw material

2). Capacity ( t/h)

3). Heating Source ( Coal, natural gas or oil)

Upon we got your message we shall give you our favorable offer in short time.