1. Taiwan Delta frequency controller, insured the duration and precision of our wood edge banding machine.

2. PLC use LG brand, air cylinder use SMC from Japan, HIWIN liner track, Honeywell limitation switch, Taiwan CPG conveyor motor, all key parts we choose market tested best brands to try to guarantee our machine performance and let our customers enjoy to use our machines.

3. Independent lifting up and down system, simple and convenient.

4. Precise encoder control, high speed.

5. Special polishing structure, motor angle can be universal adjusted, make the PVC/Acrylic/ABS/Veneer band polishing and buffing to the best.

6. Glue spray clean system is optional, it's good to remove the glue and dirty on MDF/Wood during edge banding process.

7. PUR edge band function is optional to give you more durable, no gap banding experience!

8. Veneer/wood edge band is optional to be installed!

Funtions: Corner Rounding / Gluing / End Trim/ Rough Trim / Fine Trim / Scraping / Buffing

Certifications

Detailed Images

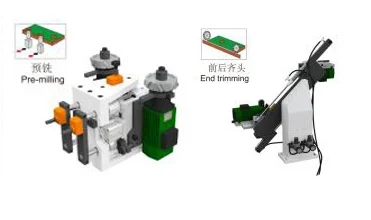

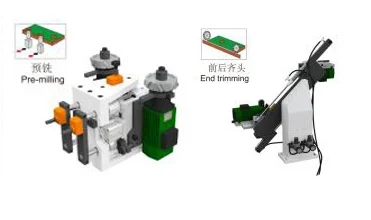

Pre-milling and End Trim

Equipped with double diamond blades, remove the possible waving texture on edge to achieve better edge banding affection.

End trim running through precise liner track, automatically tracked with mould and fast cut with high frequency high speed motor, guaranteed the plain and complete of cutting side.

Buffing and Gluing

The buffing device adopts cotton material polishing wheel to sand the finished edge band more smoothly.

Gluing facilities use special structure to evenly spread the glue on both banding panel and band, ensure a more solid adhesion force.

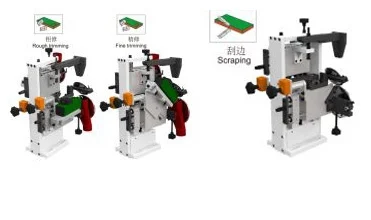

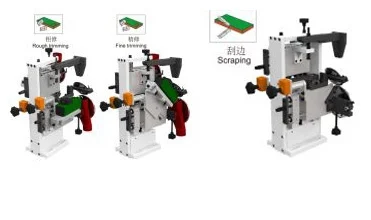

Fine Trim / Rough Trim and Scrapping

Fine and rough trim facilities are used to remove the extra material on band, it adopts mould automatically track and high frequency high speed motor, ensure the plain and smooth of work piece top and bottom parts.

Scraping units used to remove the texture which might happened during trim processing, guarantee the band to be smooth and plain.

Grooving

Grooving is a optional function for edge banding machine. It's used to slot out one groove on panel to install glass, back panel etc.

Our Company

Contact Us

To get response right now, plz email or call /WeChat /Whatsapp Mr. Daniel at +86-18665405636

To follow us on Facebook, plz visit: https://www.facebook.com/ileabon

To watch our machines operation video on youtube, plz visit: https://www.youtube.com/user/welfecn/videos