Высокоскоростная машина для выдувания полиэтиленовой Пленки HDPE ABA LDPE 3

- Категории: Blown Film Production Line >>>

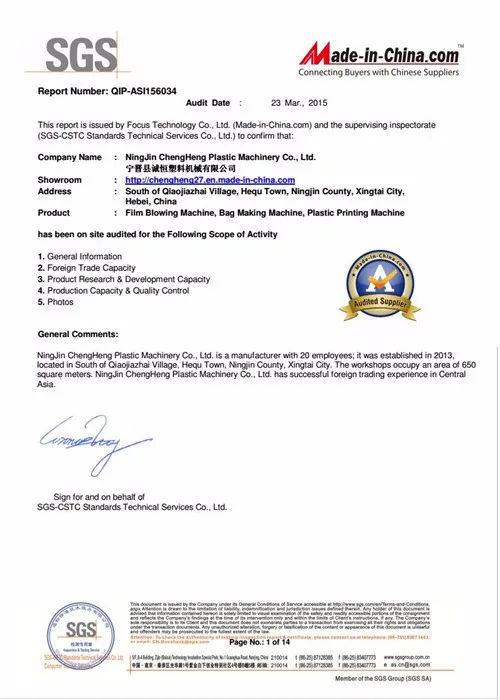

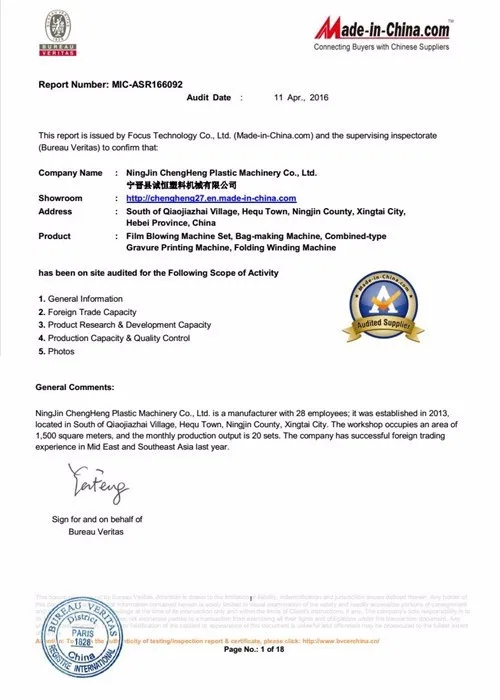

- Поставщик: Hebei,Chengheng,Plastic,Machinery,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Product Application

3-layers ABA co-extrusion blowing film machine enjoys special advantages and can produce both HDPE and LDPE Film. it improve the physical toughness of film through multi-layers co-extrusion. with one main extruder providing material for outer and inner layer. it reduces one man extruder configurations and achieves energy saving and low consumption.

| \t | \t | |||

| \t | \t | \t | \t | \t |

| \t | \t | \t | \t | \t |

| \t | \t | \t | \t | \t |

| \t | \t | \t | \t | \t |

| \t | ||||

| \t | \t | |||

| \t | \t | \t | \t | \t |

| \t | ||||

| \t | \t | \t | \t | \t |

| \t | ||||

| \t | \t | \t | \t | \t |

| \t | \t | \t | \t | \t |

| \t | \t | \t | \t | \t |

Main Features

1. Ceramic heater: Fast heating and save power cost

2. Simens motor and Inverter control

3. SCREW: SACM645 WITH BIAMETALICC TREATMENT 5 YEAR WARRANTTY

4. Special ambdoidal board 1set

5. Auto Ioader with dryer good for using recyle material 2set

6 .Corona treatment 1 set

Optional Device:

1.Automatic Hopper Loader with dryer

2.360°rotary die head

3.automatic back to back winder

4.Film Surface Treater

5.Oscillating Take Up Unit

5.IBC(Internal Bubble Cooling Computer Control System)

6.EPC(Edge Position Control)

7.Chiller

8.Heat Slitting Device

9.Gravimetric Dosing Unit

10.Thickness Measurement

11. Mechanics screen changer

12.Edge material recycling machine

Machine Parts

Screw: SACM645

SACM645 steel with hard with nitrogen with bimetallic treatment,5years warranty

Main Features

Heater: Ceramic heater

Advantage: Fast heating and save power cost

Machine Parts

Name: Die head

Brand: Taiwan quality

High quality mould can make film thickness uniform

Main Features

Name: auto winder

Original: China

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

| \t | |

| \t | \t |

| \t | \t |

| \t | \t |

| \t | |

| \t | \t |

| \t | \t |

| \t | \t |

PE film blowing machine

91.8% Response Rate

PP film blowing machine

91.8% Response Rate

91.8% Response Rate