Автоматическая Шестигранная гайка изготовление высококачественного винтового сверления индивидуальная

- Категории: Metal Forging Machinery >>>

- Поставщик: Xuchang,Huarui,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Description

FEATURES OF TAPPING EQUIPMENT

* Pneumatic cylindrical pusher allows you to adjust the stroke length.

* Speed thread rolling, parameters and productivity of the equipment controlled by a programmable interface and the inverter.

* The alarm system warns of failures, the absence of blanks, parts jams, overload, abnormal air pressure

* Device sorting defective product automatically removes defective products.

* Design of the tool unit can quickly replace hardware tools.

* Speed thread rolling, parameters and productivity of the equipment controlled by a programmable interface and the inverter.

* The alarm system warns of failures, the absence of blanks, parts jams, overload, abnormal air pressure

* Device sorting defective product automatically removes defective products.

* Design of the tool unit can quickly replace hardware tools.

WORKING PRINCIPLE OF RNT SERIES NUT TAPPING EQUIPMENT

The stamped blank of the nut is fed to the intermediate hopper and then to the receiving hopper of the nut-cutting machine. From the hopper, the workpiece falls along vertical guides into the thread cutting unit, where the pneumatic pusher presses the nut workpiece against the driven rotating tap, pushing it along the working part of the tap rod, forming an internal thread. Finished nuts are dumped from the tail end of the curved tap into the finished product container.

Product Paramenters

Model | M8-Z4 | M12-Z4 | M16-4Z | M20-4Z | M24-4Z | M30B-D2G | M36-2Z |

Model | |||||||

Tapping range | M6-8 | M10-12 | M16 | M20 | M24 | M30 | M32 |

Output (pcs/min) | 45-60 | 28-37 | 17-19 | 10-12 | 7-9 | 4-7 | 3-6 |

Number of units | 4 | 4 | 4 | 4 | 4 | 2 | 2 |

Total power | 4.7KW | 6.3KW | 10.2KW | 10.2KW | 12.5KW | 16.5KW | 16.5KW |

Weight | 1T | 1.2T | 1.8T | 2.2T | 2.6T | 2T | 2T |

Pictures of machines

End products

* Lock nuts: DIN 980, 982, 985, 6924, 6925, 6926, 6927

* Square weld nuts: DIN 928, 929

* Square nuts: DIN 557

* Square low nuts: DIN 562

* Hex low castle nuts: DIN 937, 979

* Hex low nuts: DIN 439, 936

* Hex Nuts: DIN 555, 934, 971, 2510, 6915

* Hexagon castle nuts: DIN 935

* Hexagon nuts with flange: DIN 6923

* Square weld nuts: DIN 928, 929

* Square nuts: DIN 557

* Square low nuts: DIN 562

* Hex low castle nuts: DIN 937, 979

* Hex low nuts: DIN 439, 936

* Hex Nuts: DIN 555, 934, 971, 2510, 6915

* Hexagon castle nuts: DIN 935

* Hexagon nuts with flange: DIN 6923

Related Machine

Hot forging nut former machine cold forging nut making machine

The six-position cold heading machine is a universal solution for the production of all groups of nuts with improved mechanical properties, excellent quality and relatively low production costs.

For the production of M6 and M8 nuts, five-position cold heading machines are used. For the production of M10 nuts and more, it is recommended to use six-position cold heading machines. This recommendation is based on the quality of the metal. The technology for the production of a nut from low-carbon steel on six-position presses allows to reduce the requirements for the quality of the metal and to obtain the final product of very high quality.

For the production of M6 and M8 nuts, five-position cold heading machines are used. For the production of M10 nuts and more, it is recommended to use six-position cold heading machines. This recommendation is based on the quality of the metal. The technology for the production of a nut from low-carbon steel on six-position presses allows to reduce the requirements for the quality of the metal and to obtain the final product of very high quality.

Packaging and Shipping

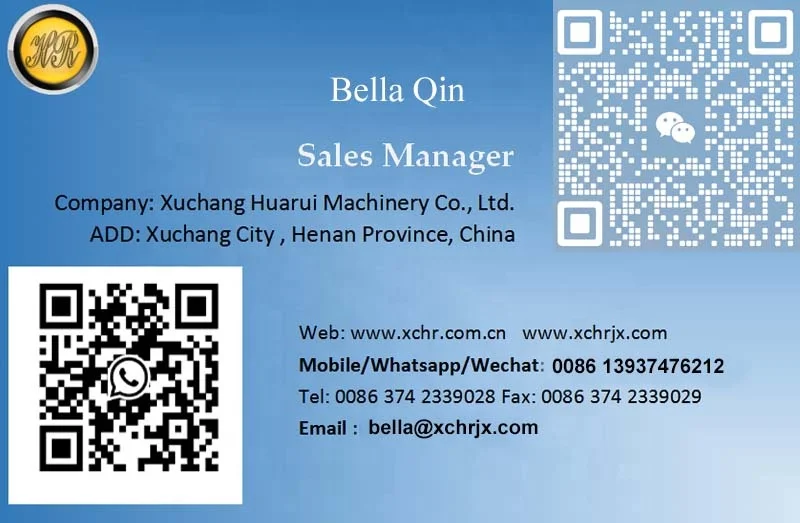

Contact Us