Автоматическая высокоскоростная Резьбовая машина для гипсокартона резьбонарезная машины изготовления гаек

- Категории: Metal Forging Machinery >>>

- Поставщик: Foshan,Youcheng,Fastener,Mold,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Technical parameter for one die two below anto heading machine:

| PRODUCT INFORMATION |

| Model | M4-40B/C |

| Max cutting off Length(mm) | 40 |

| Max cutting off Dia (mm) | 4 |

| Stroke (mm) | 62 |

| Main Motor (kw) | 15/0.18 |

| Capacity (Pcs/Min) | 120-180 |

| Weight (kg) | 970 |

| Volume (L*W*H) (m³) | 1.5*0.9*1m |

Functions of heading machine:

(1). The machine belong to the cold heading machine, the function is the first molding and the second punching products, which is mainly used for forming the heads of the screw products, the work principle is line materials calibration, accessing lines, sending materials to the main mold, first punching initial forging, and second punching the formed blank materials and withdraw. The work gets done without any letup, the production capacity can be up to about 150-180pcs per minute, which belongs to the more advanced products in the current technology.

(2). Upsetter various materials: Common steel, carbon steel, stainless steel, copper, aluminum, and alloy steel etc with widely functions. (For the stainless steel and alloy steel, can heat them to the appropriate temperature with the heater, and can upsetter.)

Apply:

The machine can make the common products such as the common self-tapping screw, electric screw, micro-screw, socket head cap bolts, self drilling screw, fiber plate screw etc. For an example PKO can upsetter other non standard abnormal hardware and metal products.

Production Flow:

Brief introduction of processes and machines needed:

(1). Pull the coarse line to the line patch needed. (Wire drawing machine)

(2). Adjust, produce, and form the head of screw on the heading machine. (Screw heading machine)

(3).Grind tooth on the coil thread rolling machine, and form the screw completely (Thread rolling machine)

(4). Treat the semi-finished screw in the heat treatment according to the standard (Heat treatment furnace)

(5). According to the requirements, process plating etc. (Zinc plating machine)

(6). Packing and out of factory

Finished Products:

one die two blow anto heading machine M4-40B/C

| PRODUCT DISPLAY |

Feature 1. Rich experiences with strong technical team 2. Provide complete line solution and technology 3. High quality of machine and mold 4. Long life time, Less maintenance 5. 24 hours online service and best after-sale service |

| For more products information | CONTACT US > |

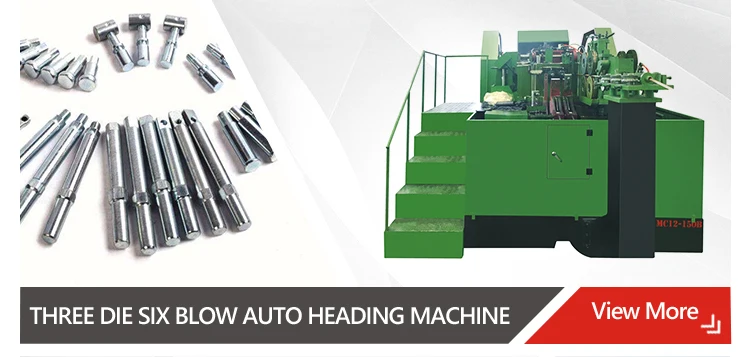

| MAIN PRODUCTS |

| For more products information | CONTACT US > |

| COMPANY OVERVIEW |

| For more company information | CONTACT US > |

| CONTACT US |

We can make many specifications according to your request! For more information, please contact us! | |

| Mob(whatsapp or wechat): | +86-13413225690 Sofia |

| Fax : | +86-757-8686 5699 |

| QQ: | 2730246962 |

| Address: | Jinsha shangliang development zone, Danzao town, Nanhai Dist, Foshan city, Guangdong province,China |

| FAQ |

Q1: Why do we choose Youcheng Technology ? A1 : We are professional manufacturer of various kinds of fastener making machine, which located in Foshan city of Guangdong province , Which has more than 30 years experience for producing fastener production line equipment and fastener mold .For these products, Not only have rich experience to produce high quality machine and fastener mold , but also with strong technical team as basis. Q2: Have you exported machine to overseas market ? A2: Yes . We has exported machine to Russia, Malaysia, India, Vietnam, Indonesia,Turkey, Spanish, Egypt, Sri Lanka etc. Q3: Is there any quality warranty and after service ? A3: The warranty of mechanical portion of the equipment shall be a year after you received the equipment; And help buyer installation and commissioning the equipment , and free training operator. Q4: If there any quality problem of your machine and spare parts , what should I do ? A4: Within one years, if machine have any quality problem. we will repair for free.But if damaged parts will be replaced by offered of charge .we provide lifelong tracing service, supply equipment parts and relevant maintenance at favorable prices, and give user technical guidance free of charge. |

| BACK TO HOME PAGE > |