Индукционная печь для

- Категории: Кузнечное оборудование для металла >>>

- Поставщик: Chengdu,Duolin,Electric,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

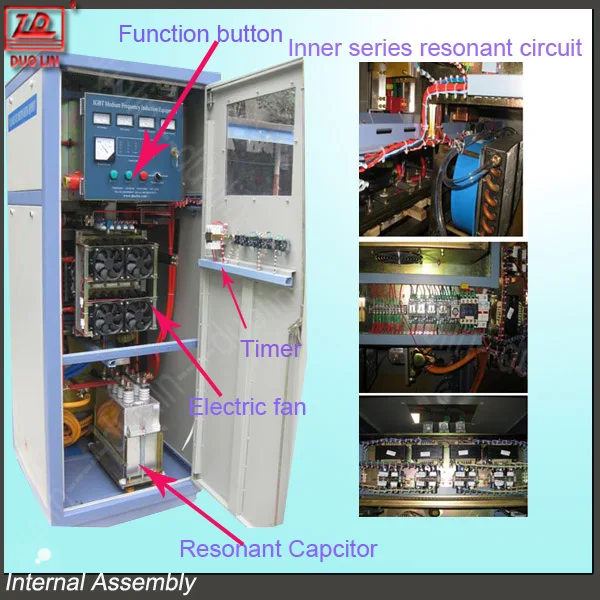

Details:

Technique Parameters

Model | MFP-100 | MFP-160 | MFP-200 | MFP-300 | MFP-400 | MFP-600 | MFP-800 |

Rated Output Power | 100KW | 160KW | 200KW | 300KW | 400KW | 600KW | 800KW |

Working Frequency | 1-10Khz | 1-10Khz | 1-10Khz | 0.5-8Khz | 0.5-8Khz | 0.5-5KHz | 0.5-5KHz |

Power Capacity | 125KVA | 200KVA | 250KVA | 380KVA | 500KVA | 750KVA | 1000KVA |

Input Power | 380V/50Hz 3 phase 4 lines | ||||||

Duty Cycle | 100% | 100% | 100% | 100% | 100% | 100% | 100% |

Working Voltage | 340V-430V | ||||||

Input Current | 160A | 260A | 330A | 500A | 650A | 1000A | 1300A |

Cooling water Flow | 10-20m³/h | 10-20m³/h | 10-20m³/h | 25-35m³/h | 25-35m³/h | 25-35m³/h | 50-60m³/h |

Weight | 170KG | 206KG | 210KG | 340KG | 340KG | 600KG | 620KG |

Size(mm) | 620*680*1630 | 720*780*1800 | 820*780*1800 | 920*930*1950 | 920*930*2080 | 1500*800*2000 | 1500*800*2000 |

Feature

1. high speed induction horizontal forging machine can heat billet diameter from 25mm-80mm.

2. Maximum production rate 0.4-0.45T/Hour

3. high speed induction horizontal forging machine can heat Carbon steel, Stainless steel, Alloy steel, Aluminum Brass and Others

4. Uniform heating temperature is good for mold of press machine.

5. Heating rapidly reduces oxide skin on billet

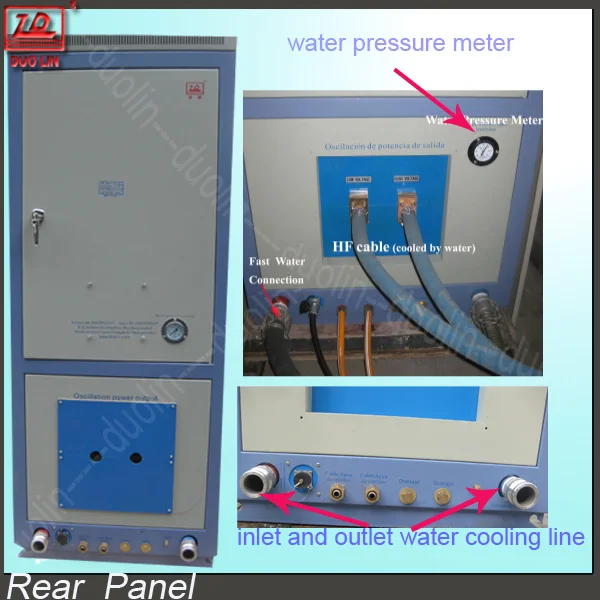

5. Quick water connections

6. IGBT inversion technology & LC series circuit design achieve energy saving up to 15%-30% compared with SCR technology high speed induction horizontal forging machine

7. Diode rectification technologies ensure high power factor –more than 0.95

8. Color and language printed according to customer's request

Application

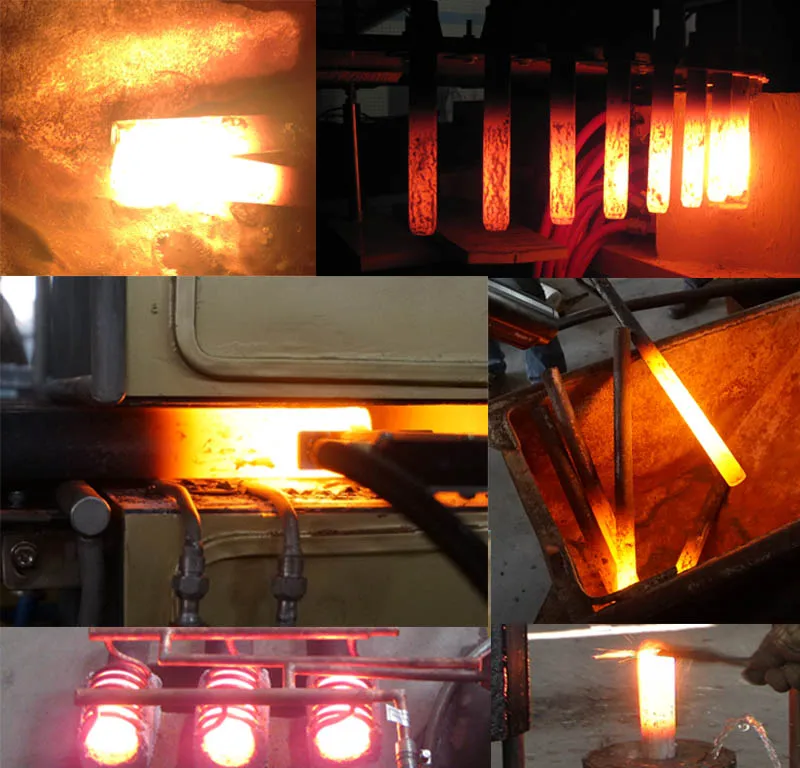

Application in Industry

Heating before forging

Packing &Package

Our service

1. Reply the email within 24hours. 6 staffs work for Export Department,

2. Two of them who have experience in sales, installing and after-service more than 7 years.

3. on-site engineering service

4. 12 months warranty

5. Color, language and logo can be printed according to your demands.

6. Plywood cases customized for sea transport.

Company Information

Supplier of accessories

Certification

FAQ

1. How many years can it work?

Many factors, usually 5-10years, depends on your operation, cooling water, maintenace. etc

2. How many days can we get the spare parts?

Usually send out in 1-2days.